13/10/2023 – Andritz at Since 2023

Andritz at Since 2023

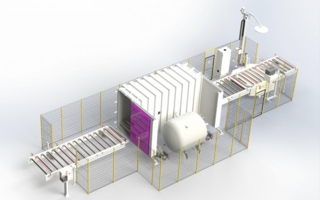

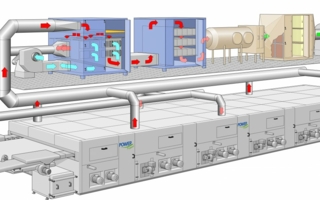

Andritz will be presenting its innovative production solutions for nonwovens and textiles at Since in Shanghai, China, from November 8th to 10th, 2023. ...