03/05/2023 – Itma – Swedish textile machinery

Automation in focus

TMAS – the Swedish Textile Machinery Association members will showcase state-of-the-art, fully integrated technologies with the latest automated features that enable end-to-end production of fully-finished garments and home textiles at the upcoming Itma 2023 exhibition in Milan, Italy, scheduled to take place from June 8-14.

“Technologies such as artificial intelligence (AI), machine learning and automation are becoming increasingly important in the textile industry and in Milan, Swedish companies will showcase new machines and software that can help streamline production and improve efficiency,” says TMAS secretary general Therese Premler-Andersson.

At the previous Itma show in 2019, ACG Kinna partnered with various other companies and drew significant attention with its robotic pillow filling system demonstrations. The automated units are capable of filling and finishing up to 3,840 pillows during an eight-hour shift and cover the entire process, from opening and weighing the fiber to filling the product, sewing, and packing processes.

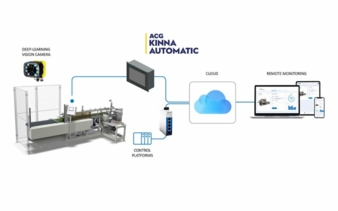

Since then, the system has been further improved, and it now incorporates new features such as an integrated marking solution, which allows customers to print QR codes, batch numbers, and dates on the pillow labels. Additionally, the system now includes unique software that can automatically detect pre-programmed faults, which will be showcased at the upcoming Itma 2023 exhibition in Milan.

Single source potential

Following its acquisition of Nowo's portfolio, Kinna has become a single-source supplier of various textile production machinery lines. Nowo's well-established portfolio primarily consists of machinery for fibre processing and quilting, including the highly successful “Nowo Vac” pillow filling system and “Noworoll” ball fibre machine.

According to Tomas Aspenskog, the company's sales and marketing manager, integrating Nowo's range into their portfolio has allowed them to oversee complete projects from start to finish, ensuring highly automated production of pillows, quilts, and other finished products. This gives their customers several advantages, such as transparency and the elimination of bottlenecks. Aspenskog explains that customers can face difficulties when multiple suppliers are involved in building a line, which can cause misalignment and delays in completing one line component while others are still under construction.

Materials handling

Eton Systems offers automated material handling systems that utilize individually addressable product carriers to eliminate manual transportation and minimize handling. This system radically increases the time available for adding value to garments and other finished products, making it a compelling choice for textile manufacturers across Europe and the United States to bring production closer to home. This has been a noticeable trend in recent years.

At the upcoming Itma 2023 exhibition, Eton will introduce its latest software platform, “ETONingenious”. This real-time system manages, controls, and monitors production in the Eton system. ”ETONingenious” continuously collects, processes, and presents valuable product information to operators, supervisors, quality control personnel, and management. The software features a web-based user interface, runs on any browser, and does not require client installation. It can easily integrate with any existing ERP system and is Industry 4.0 compatible. Dashboards provide a clear and easy overview of production.

According to CEO Jerker Krabbe, "ETONingenious will help companies achieve their production targets by freeing up more time for supervisors, reducing throughput time, identifying bottlenecks, and enabling real-time production adjustments."

Benefits

Premler-Andersson believes that the AI and advanced automation already utilized by TMAS members, such as ACG Kinna and Eton, have the potential to revolutionize the textile industry. These technologies can improve production efficiency, quality control, and design processes.

“AI-powered systems can, for example, help detect defects in fabrics and garments during manufacturing processes,” she explains. “By using computer vision in the machinery, different defects such as stains, holes and uneven stitching can be rapidly identified and corrected at an early stage. Predictive maintenance is another benefit. AI is being used to monitor machines and predict when they are likely to need maintenance. This can help prevent breakdowns and reduce downtime, improving overall efficiency. AI is also proving valuable in R&D for TMAS companies, enabling data from different sources to be coordinated in order to optimise product design and reduce time and costs via the sensor-controlled optimisation of a host of different parameters.”