27/01/2015 — auf Deutsch lesen

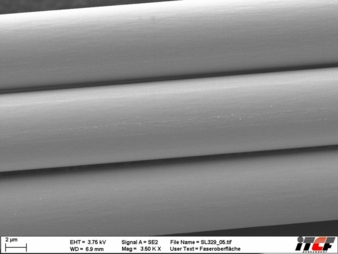

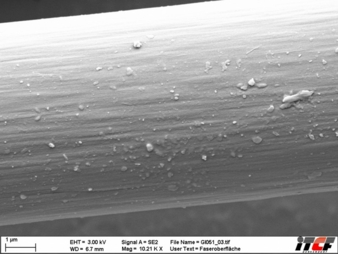

ITCF Denkendorf: Surface modification of carbon fibres

In recent years, fibre composites have made their way into leading industrial sectors due to their outstanding mechanical properties and their huge potential for use in lightweight designs. Fibre composites based on carbon fibres in particular have gained widespread use and recognition. Their extraordinary strength and toughness, combined with their low weight, mean that they are ideal for applications in the automotive, wind engineering and other technical sectors.

The interaction with the surrounding matrix – an epoxy resin, for example – guarantees that a work-piece is best able to withstand external forces. If, when force is applied, the carbon-fibre surface should become detached from the epoxy resin, the consequences are usually catastrophic. The force would then be absorbed only by the fibres and the material may fail: the work-piece breaks.

In order to counteract this, the researchers at the ITCF Denkendorf use a complex chemical process to graft polymer chains onto the surface of the fibres, thereby strengthening the adhesion of the carbon fibres to the epoxy matrix. This process can be easily transferred into industrial production.