08/12/2023 – Benninger

Latest wet processing technology

Benninger specializes in machinery and solutions for both continuous and discontinuous wet finishing of woven, knitted and technical textiles.The company is continuing to expand its offer to the textile wet processing secotor with innovations in fabric dyeing and singeing technology. Its heritage of 160 years is the foundation for ongoing progress, with today´s systems embracing sustainable production towards zero environmental impact for its global customer base.

Pioneering “Fabric Master”

A game-changing solution in Benninger´s portfolio for discontinuous dyeing is the “Fabric Master”. This jet dyeing machine produces diverse fabrics while conserving water and being cost-efficient. Its reliability and adaptability cater to present and future fabric needs, addressing industry challenges with minimal resource consumption and maximizing precision in dyeing processes. Specifically, the company´s discontinuous dyeing technology has precise control of processes and chemical distribution (DDS, CDS, PDSD), setting new standards for shortened process times, and accuracy in maintaining the required batch sizes, weight, and liquor ratio. The carbon footprint of the “Fabric Master” is designed to be the future industry benchmark for sustainability.

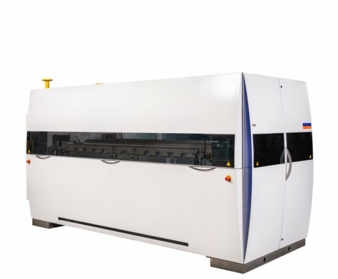

Foundation for uniform quality

The “Singe Ray” fabric singeing machine from Benninger is said to lay the foundation for uniform quality, producing a perfectly dyed and finished fabric. Its high-performance burner ensures uniform singeing effects across the fabric width, even smaller fabric widths can be worked with economically, saving energy efficiently. With a smart burner design preventing deformation due to its 2 x 2 cooling system and certified safety standards, this German-made machine is certified by the German Technical and Scientific Association for Gas and Water (DVGW). For knitted fabric processing, Benninger´s knit line solutions, installed in over 120 mills globally, offer performance and cost reduction in demineralization and bleaching processes.

Road to zero

As a system supplier Benninger is committed to environmental responibility and resource efficency. According to Rolf Schoeler, CSO Benninger AG: “Benninger solutions always focus on resource efficiency, so textile finishing plants with Benninger machines installed can be assured of particularly low resource consumption and highest productivity.”