13/10/2023 – Andritz at Since 2023

Showcasing innovative textile solutions

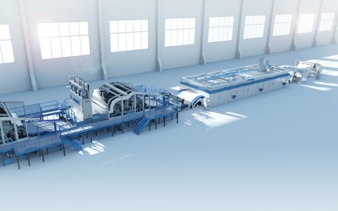

Andritz will be presenting its innovative production solutions for nonwovens and textiles at Since in Shanghai, China, from November 8th to 10th, 2023. The product portfolio covers state-of-the-art production technologies for nonwovens and textiles, including air-through bonding, needlepunch, airlaid, spunlace, spunbond, wetlaid/wetlace, converting, textile finishing, airlay, and natural fiber processing.

One of their notable developments in drylaid technology is the “CA25” card in the “axcess” range, which can achieve speeds of up to 200 m/min while maintaining the MD/CD ratio below 4:1, offering cost-effective capacity for air-through bonding, spunlace, and “Wetlace CP” processes.

Andritz focuses on comprehensive technologies for wipes, including “Airlace”, “Spunlace”, “Wetlace”, and “Wetlace CP”, with a commitment to sustainability, aiming to reduce plastic components and reuse raw materials – such as wipes that are biodegradable and/or flushable and produced from natural or recycled fibers – all with one goal in mind: to reduce and eliminate plastic components and to reuse raw materials.

In the hygiene nonwovens sector, Andritz offers complete lines and individual machines for producing materials for baby, adult, and fem care products, emphasizing high production capacity and the use of natural fibers. The Andritz air-through bonding lines deliver all the fabric characteristics of nonwovens for hygiene end uses, such as top sheets, acquisition distribution layers, and back sheets. The carding machines are the key to success in achieving perfect web uniformity and comfort. With the Andritz air-through bonding line, manufacturers can benefit from high production capacity and high performance fabrics from 16 to 80 gsm made from bi-component fibers produced at high speeds of up to 250 m/min. The air-though bonding allows including cellulosic and natural fiber in the fiber blend to improve the quality of absorbent hygiene products and reduce the consumption of plastics.

Additionally, their needlepunch portfolio and PTFE processing solutions for filtration and batt forming for glass and natural fibers will be highlighted, along with the “ProWid” technology for profile weight correction in the needlepunch industry. These innovations are said to improve product quality and open up new market opportunities.