06/06/2019 – Textile networks — auf Deutsch lesen

Zooming in on ZIM

Innovation is booming in the field of textiles, as is apparent from the funding statistics from Germany’s Central Innovation Programme for SMEs (ZIM).

Now, the SME Day of Innovation (Innovationstag Mittelstand), which takes place once a year in Berlin, has provided further evidence of this. textile network took a look around and discovered some interesting innovations.

The SME Day of Innovation was held on a greenfield site in Pankow, Berlin, with Austria as the ‘guest country’ (foreign SMEs can seek funding from their home country for collaborative development work with German businesses and institutions), and demonstrated two points. First, a full ten years after the programme’s launch, the rush of interest in this attractive form of co-financing for SMEs (from start-up size upwards) is as high as ever. Second, as is apparent in textiles as well as other industries, few developments are possible these days without scientific input from universities and industry-related institutions. Here are two examples:

Textile-based cut-resistant boots

The ‘Foot-Safe’ innovation from shoe manufacturers Reck & Sohn Schuhfabrik in Hohentengen, Baden-Wuerttemberg, is one of 800 textiles projects funded by ZIM in the last ten years. Developed in collaboration with the University of Applied Forest Sciences in Rottenburg and with partners in industry, and with a view to users in the ‘green’ professions, it is a safety boot made chiefly from textile materials and offering cut- and penetration-resistance together with toe protection. Unlike leather cut-resistant models that can reach 5 kg, a pair of these boots weighs in at just 1.5 kg.

Washable micro-electronic system

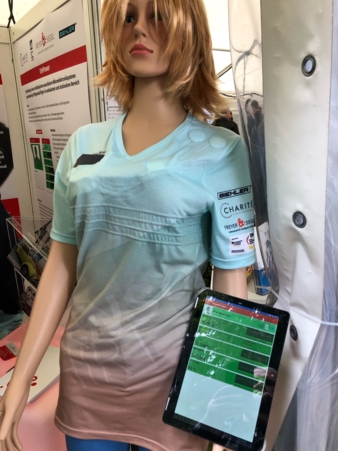

A mannequin in a green dress, iPad in hand, highlights a high-tech innovation. “EmPower” is a textile-based washable micro-electronic system for monitoring people requiring medical or social care. The prototype T-shirt has sensors close to the skin and outputs its data via an app. It can collect data on changes in position, pulse rate, breathing rate, temperature and skin moisture levels, and report these to the care centre where relevant. Involved in the project alongside electronics company Freyer & Siegel from Hennigsdorf (Brandenburg) and manufacturer Biehler were the Charité hospital and the Saxony Textile Research Institute in Chemnitz.

Technology funding for all sectors of industry

The ZIM programme, launched in 2008, has opened research and development doors for tens of thousands of SMEs, frequently involving academic institutions as partners. The Federal Ministry for Economic Affairs and Technology makes available subsidies of well over EUR 500m a year. This allows some 3,000 new projects a year to be bump-started, some of them with foreign partners from outside the EU (e.g. Canada, South Korea, Taiwan, Vietnam). ZIM funding is available for single-company projects and collaborations, as well as for developments by networks of teams.

Solo developments, of course, can also be supported, as demonstrated by the example of Peterseim, manufacturers of knitted fashion and functional knitwear in Mühlhausen, Thuringia. The company, founded following German reunification in 1990, seeks to bring to market new forms of comfortable, low-density knitted heat- and cold-resistant clothing, for which it uses a new non-woven material composed of silica aerogel fibres. At the heart of the innovation, explains Director André Niemann, is the technology required to integrate the material into an elastic 3D knitted framework.