15/06/2022 – Techtextil: Baldwin

Managing high energy costs with precision-spray system

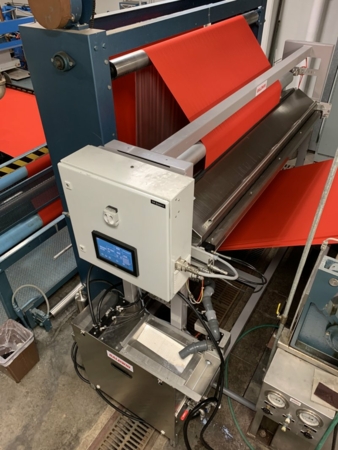

Baldwin Technology Company Inc. will showcase its sustainable TexCoat G4 finishing system at Techtextil in Frankfurt as well as at ITM in Istanbul (hall 12, booth 1211).

The TexCoat G4 non-contact precision-spray technology helps textile finishers up their game by enabling consistent, high-quality finishing, with zero chemistry waste and drastically minimized water and energy consumption.

With a cost-sensitive global economy and an increased focus by brands and consumers on the environment, customers are placing a premium on sustainability in textile production. TexCoat G4’s non-contact spray technology offers numerous advantages compared to conventional methods of applying finishing chemistry. With Baldwin’s innovative system, the chemistry is precisely distributed across the textile surface and is applied only where it is required, on one or both sides of the fabric. The non-contact technology eliminates chemistry dilution in wet-on-wet processes, allowing full control of maintaining consistent chemistry coverage rates. Plus, pad bath contamination is eliminated, and changeovers are only required when there is a change of finish chemistry.

Changeovers are easily and quickly performed, thanks to recipe management, including automated chemistry and coverage selection. Furthermore, the system offers automated speed tracking, fabric-width compensation, and real-time monitoring to track system uptime, performance and chemistry usage, as well as active care alerts.

In addition, the TexCoat G4 system can process a wide range of low-viscosity water-based chemicals, such as durable water repellents, softeners, anti-microbials, flame retardants and more. Baldwin’s innovative technology utilizes the same chemicals used in the traditional pad bath, and no special auxiliaries are required. The recipe is adjusted by increasing the concentration and reducing the pickup by a corresponding amount, so that the same level of solids is applied. Some applications, such as durable water repellents, are only applied on the face of the fabric, instead of the traditional method of saturation through dipping and squeezing. Drier fabric entering the stenter means lower drying temperatures and faster process speeds. Single-side applications also open up the opportunity to process back-coated or laminated fabrics in a single pass of the stenter, instead of two passes.

Techtextil: Hall 12, booth D 79