03/05/2019 – Techtextil: Follmann — auf Deutsch lesen

Coatings and Adhesives for Technical Textiles

Under the slogan „Coatings and adhesives for technical textiles“ Follmann will be presenting its wide range of products for technical textiles.

The products range from water-based polymer dispersions, PVC plastisols, pigment preparations and coatings for digital printing to polyurethane hot melts for textile lamination.

The leading international trade fair for technical textiles and nonwovens is an important platform for Follmann to present its range of functional coatings to an interested audience. For the first time at Techtextil, the family-owned company from Minden will also be presenting its water-based coatings for digital printing media as well as the polyurethane hot melts for textile lamination.

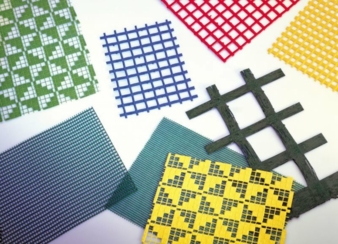

PVC plastisols und water-based polymer dispersionen for rigid and flexible substrates

Functional coatings are used almost everywhere today. They should be able to reliably perform their various tasks both in everyday life, such as in the operating room, and under extreme conditions, such as on the high seas. With PVC plastisols and water-based polymer dispersions from Follmann, a wide variety of substrates, such as roofing membranes, geotextiles, transport or conveyor belts, are optimally equipped and adapted to almost any desired requirement. Depending on the conditions of the application, the properties a product should have, such as UV stability, flame retardancy, seawater resistance or slip resistance, can be combined almost unlimitedly. With Follmann’s tailor-made solutions, a wide variety of ideas and wishes can be realised.

Pigment preparations for coatings

Whether it’s for PVC plastisols for floorings, cable sheathings, films, synthetic leather, toys or PUR systems – Follmann’s solvent-free pigment preparations are excellently suited for colouring liquid plastics and polyurethanes. They provide optimum pigment dispersions, high colour brilliance and intensity, and excellent light fastness and thermal stability. These low-fogging and low-migration, VOC-free pigment preparations also excel with broad compatibility and very good storage stability. The pigment preparations specially developed for industrial applications are particularly suitable for PUR systems, coating systems and typical CASE applications. They also impress with perfect pigment dispersions, brilliant and pure colour shades, broad compatibility and excellent storage stability, and they are VOC- and solvent-free. In addition to a standard range, Follmann naturally also offers custom solutions, i.e. solutions adapted to individual customer requirements.

Water-based coatings for digital printing media

For the first time at Techtextil, Follmann is presenting its water-based, ready-to-use coatings for digital printing media, which have enriched the company’s portfolio since March 2018. They can be used to digitally print on numerous substrates such as paper, textiles, foils, nonwovens, wallpaper and canvas in further processing. The environmentally friendly received coatings are suitable for various ink and colour systems – be it water-based pigment or dye inks, latex inks, solvent inks or UV-curing inks.

The functional surface coatings enable high-quality printing results and guarantee outstanding colour brilliance. Thanks to the high drying speeds, the printed media can be processed quickly.

Polyurethane hot melts for textile lamination

As the latest addition to its portfolio for textile applications, Follmann will be showing its new polyurethane hot melt adhesives for industrial lamination of high-performance technical textiles at the trade fair. The hot melts are tailor-made for various applications such as the manufacture of safety and work clothing, breathable sports articles, filter media, automotive interior decors, medical textiles or abrasive carriers. The reactive, moisture-curing products offer excellent adhesion properties on a wide variety of substrates and high initial strengths compared to water- or solvent-based systems. In addition, the polyurethane hotmelt adhesives have excellent temperature resistance, a soft and highly flexible adhesive joint, high hydrolysis and wash stability and, last but not least, high process efficiency in a wide variety of production layouts.

Follmann at the Techtextil

Hall 3.0, stand D 73