26/10/2015 — auf Deutsch lesen

ITMA 2015 – Memminger-Iro: Perfect yarn tension

When it comes to leading-edge processing technology for yarn feeding, control systems and lubrication technology for knitting machines, Memminger-Iro is the market leader. Latest innovations are: MSF 3 ATC storage feeder based on the MSF 3 CAN with 57V DC is fitted with the Active Tension Control (ATC) sensor for controlling yarn tension.

Used together with the GTN controller unit it enables central setting of the yarn tension on single units, groups of units or on all the units together. The control system ensures that the yarn tension at the yarn outlet of the MSF 3 ATC is not influenced by external factors such as the bobbin size or the yarn quality and maintains the preset values at all times.

An additional feature is the yarn length measuring function already present in the GTN unit for the MSF 3 CAN and for the positive feeders mounted on the knitting machine. Promofeed is the next generation of yarn-tension-controlled feeders for feeding elastic and non-elastic yarns to knitting machines. Yarn tension range is from 0.5cN to 100cN. The unit is simple in installation and operation.

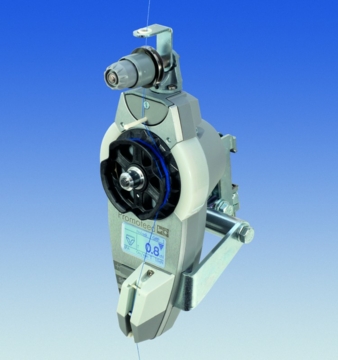

The fabric scanner Knit Scan is a contactless system and leads to a huge reduction in second-grade fabric caused by broken needles on large diameter circular knitting machines. The unit is self-adjusting to the fabric and therefore very easy in handling and operating. Due to the fact that the scanner head does not touch the fabric, sensitive fabric qualities can also be detected.

[ITMA 2015, hall 5 booth H5-B121]