15/04/2019 – Techtextil: TITV Greiz — auf Deutsch lesen

Interactive textiles go reality

The challenge in the development of smart textiles is, to make the interesting ideas for products manufacturable and usable.

Difficulties, which have to be solved, are effective production technologies as well as the improvement of the durability, electric supply and reliability. Even though technologies are developed and implemented in the form of prototypes, but the realisation of specific products is frequently not feasible. Many innovative concepts end up being one time demonstrators that are not pursuit further.

Is the intention to launch sustainable products on the market, it becomes inevitable to merge textile-, electronic-, hard- and software industry.

Especially in the interior design is the individual lighting design a big topic. As it succeeds in creating a fundament for a safe and pleasant attitude towards life, emanate an ambiance which conveys a more comfortable feeling. Well-being and safety are aspects which are approved and demanded by the client. Hence, individual and creative lighting concepts for different applications are sought-after. Areas of applications reach from interior for automotive, advertisements, exhibitions, event to interior design for flats, shops, stores, hotels, gastronomy and public institutions.

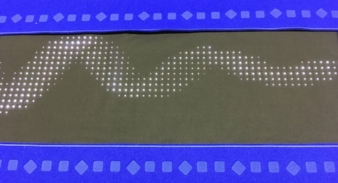

For those areas of application was the “flexible display for individual operable lighting design” developed. The chosen combination of automatic manufactured textile light matrix, programming of the software for control-ling the display through a textile touch pad, design of electric supply and reliability of the electronic were the significant challenges of this innovation.

For an efficient manufacture of individual lighting designs on top of textile surface is the FSD-technology (functional sequin devises) optimal suitable. Only through this technology it is possible to efficiently manufacture an extensively lighting design based on textiles. The LEDs are fed and placed fully automatic on an embroidery machine with a modified sequin attachment. Corresponding to the conceived circuit, the conductors are embroidered with an electric conductive thread and interconnect the FSD. 1200 FSD were automatically embroidered this way on a surface of 0.9 x 0.35 m.

The frames are automatically generated through a self-developed script. You could load existing pictures or video sequences, which are converted into the required format. Beside the visual display of pictures and video sequences, it is also possible to animate fade-in of momentarily information (e.g. time, weather and temperature) with the script. The options and control are managed through the textile touch pad.

To control the textile FSD-Display with a textile touch pad and its corresponding touch sensors, a specific manufactured electric conductive fabric is used. The interface between touch pad and display are wireless connected. This enables an unrestricted positioning of the control panel in the interior. Build upon wireless transmission through Bluetooth Low Energy, it is a simple task to implement a navigation for the FSD-Display with an app.

A big step into the distribution of individual lighting designs will be achieved through the improved and auto-mated FSD manufacturing technology, simple installation as well as the reliability of the products.

In 2017 the market volume of smart textiles accounted 230 million Euro just in Germany. Forecast estimate, that this market volume will be increased to 730 million Euro in 2022 and 4.2 billion Euro in 2030.

The challenge in development of smart textiles is to make ideas of products applicable.

With the FSD-Display for individual lighting concepts this task is achieved.

TITV Greiz at Techtextil

14.–17. May 2019

Hall 4.1, booth L 46