23/05/2016 – Beba Mischtechnik — auf Deutsch lesen

Mtex: Foam mixers like cocktails

Beba foam mixers are used in a wide variety of applications. In the food industry, these mixers can be used to produce creams, whipped cream, doughs and confectionery of any kind. In the textile industry, the mixers are needed to foam chemicals that are applied to textiles to lend them new properties.

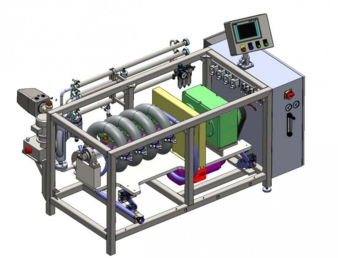

This embraces everything from Scotchgard or Teflon coating to the automotive sector, where predominantly flame retardant substances are applied to interior fabrics. Beba foam mixers are found in many other applications as well. Curtain fabrics endowed with sun protection properties, for example, also use the foam mixers from Beba. Perhaps the best way to explain how they work is to compare them to the principle of a cocktail shaker: Product pumps transport the medium to the mixing tubes.

Flowmeters for medium and gas ensure that the right amounts are in the mixing head at all times. Static mixing elements are located in the mixing tubes which are arranged around an oscillating shaft. Foam is produced by jiggling the medium and the gas by means of oscillation. Since the system is under pressure, the finished foam can be conveyed for further processing to the downstream production equipment and applied to the substrate. At mtex+, it will be possible to view the BM800 model with oscillating mixing head, which is the standard unit for the most common applications.