02/03/2022 – Textile construction — auf Deutsch lesen

New geogrid composite saves up installation time

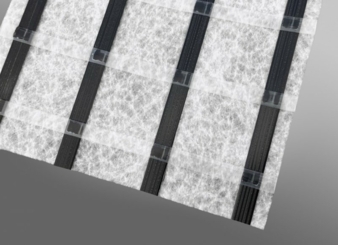

Freudenberg Performance Materials presents a new geogrid composite. Aimed at increasing the efficiency of construction projects, the product consists of a reinforcing grid bonded to a separation and filtration nonwoven geotextile.

When weak subgrade soils are present, most infrastructure projects such as the construction of traffic areas require installation of two products: a geogrid to reinforce the granular layers of the subbase and a nonwoven geotextile for filtration and separation. “This means that the same work has to be done twice to purchase two products, get them to the site, manage stock and lay the geogrid and the nonwoven geotextile,” explained Tamás Szatmári, Head of Application Management. “By providing the three required functions in one product, EnkaGrid MAX C substantially cuts complexity and costs for every stakeholder involved. Installation, for example, can be completed up to twice as fast.”

EnkaGrid MAX C is made up of a biaxial geogrid bonded at intervals to a needle-punched nonwoven geotextile. The bonding method chosen guarantees optimal interlocking of granular soils with the geogrid. The new geocomposite can be ordered in tensile strengths ranging from 20 to 80 kN/m. It is supplied on rolls with a width of five metres. “The geogrid composite comes with extensive support offered by our team of experienced Application Managers. They assist engineers and clients from feasibility study to design and execution.”, concluded Szatmári.