19/05/2016 – Truetzschler Nonwovens — auf Deutsch lesen

Nonwovens are in our DNA

Nonwovens have great significance for our daily life. They are indispensable items in the household, at work and during leisure time.

Tea bags, diapers, jackets, cars, surgery equipment and waste incineration plants are no longer conceivable without them. It is a fascinating world and Truetzschler Nonwovens & Man-Made Fibers is part of it. The company is a well-known textile machinery supplier with a broad range of products.

The Man-Made Fibers branch comprises spinning plants for carpet yarns (BCF – Bulk Continuous Filament) and industrial yarns. Whereas machinery and complete production lines for staple fiber based nonwovens constitute the company's Nonwovens branch. The diagram (right) gives an overview of the nonwoven technologies offered.

The roots of Truetzschler Nonwovens

Truetzschler Nonwovens combines the expertise and the experience of the three previously independent companies Fleissner, Erko and Bastian. Truetzschler, a family-owned group of textile machinery suppliers based in Moenchengladbach, gradually took over the respective technologies since 2005.

Fleissner: In 1848 Johann Christian Fleissner started his own business by leasing a forge in the Bohemian city of Asch. He soon began to supply machinery to the flourishing textile industry. 1929 the patent of the through-air drum was granted to Hans Fleissner, a technology still used today for drying fibers, nonwovens and textiles. After World War II the company relocated to Egelsbach near Frankfurt am Main. The company delivered the first nonwoven production line in 1973.

The most well-known product today is the Fleissner AquaJet, a leading solution for spunlacing or hydroentangling. Moreover, Egelsbach supplies machinery for thermal and chemical bonding, drying and finishing.

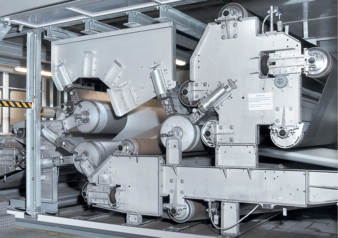

Bastian: In 2012 Truetzschler Nonwovens acquired the assets of Bastian. Founded in 1973, the company soon became a first address for winding technologies for both the nonwovens and film industries. In 2007 the 1,000th winder was delivered. Today, Bastian winders are designed in Bielefeld and manufactured in Egelsbach.

Erko: Erko GmbH started in 1993 in Duelmen as a manufacturer of switchgears but soon expanded into the nonwovens machinery field. Today the site adds machinery for fiber opening and blending, web forming and needling to Truetzschler Nonwovens' product portfolio.

Truetzschler Nonwovens today

The broad range of technologies allows Truetzschler Nonwovens for supplying complete production lines from fiber preparation to winding. For key processes such as web forming and web bonding alternative technologies are offered to cope with the various fiber raw materials and to establish the desired nonwoven properties.

Active process development

Mastering the physical and chemical processes taking place during nonwovens production had already played a major role for Fleissner. Today the various process technologies are significant competencies of both Duelmen and Egelsbach.

The company maintains two fully-equipped technical centers. On one hand customers can make use of them for testing new product ideas. On the other hand they provide Truetzschler Nonwovens' engineers the ideal place to develop new machinery and processes. One example is the new spunlacing process for so called flushable wipes made from wet-laid webs - the first outcome in 2014 of the ongoing cooperation with Voith Paper.

Turnkey production lines

A few years ago Truetzschler Nonwovens took the first step from being a machine to a complete line supplier. With this decision a new focus arose: besides the improvement of single components R&D becomes responsible for overall line productivity and resource consumption as well as for final product quality. Ordering a complete line out of one hand significantly reduces the process risk for the customer because all components are tailor-made and aligned with each other.

Innovative machinery

Innovation fuels the nonwovens industry and it fuels Truetzschler Nonwovens. Last year's ITMA in Milan has been the hour of birth for a real novelty which brings an entirely new kind of nonwovens into the world. Truetzschler Nonwovens introduced an exchangeable structuring shell for the thermobonder drum. Until this time thermobonded nonwovens, i.e. webs which are bonded by hot air flowing through them, always were bulky and soft with a plain surface. No machine and no process had been invented so far to thermobond and structure nonwovens similar to structured spunlaced material in one process step. Now the patent-pending structuring shell makes these products possible.

A thermobond drum oven equipped with such a shell produces bulky materials with bold and resilient 3D patterns. Without the shell, the same line manufactures plain qualities. Since the shell is exchangeable, the producer gains flexibility and can easier adapt to market requirements. Moreover, existing thermobonding lines can be retrofitted. The door to even more functional nonwoven fabrics used for hygiene, filtration or insulation applications is thus pushed wide open.

Author: Jutta Stehr