06/06/2024 – Start-up — auf Deutsch lesen

Completely new weaving process in progress

An entirely new class of woven fabric is possible thanks to the V-loom technology from the German start-up Casmue. The company presented its innovation to the public for the first time at Techtextil 2024.

“Cradle to cradle” – developer Sybille Castens sees this principle of a closed ecological cycle realised to the maximum in various possible applications of the weaving technology she has developed. The V-Shed is an invention that opens up completely new applications and products for the weaving process. For a manufacturing process that has not only been known to mankind for at least 10,000 years, but has also been further developed, such revolutionary innovations are very rare. While innovations in the past have focussed on weft insertion, the V-Shed is now focusing on the shed. And in such a way that it has a considerable influence on the weft insertion options.

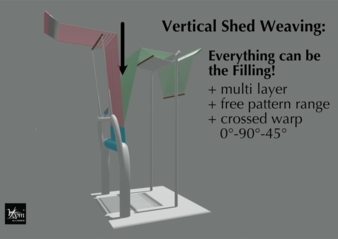

The V-shed initially turns the weaving process “upside down”.

The shed - usually a horizontal channel between the upper and lower warp threads – is turned vertically. This is still familiar from the ancient weight loom, which was in use until the early Middle Ages. In contrast to these antique methods, however, the V-shed is not enclosed at the top by warp threads, i.e. it does not form a tunnel, but a V-shaped opening that is completely free at the top. The warp threads are not fed from the top, but from both sides, so that the V-shed only consists of the part known as the "front shed" in technical jargon. The second part of the shed, the so-called "rear shed", which turns the shed into a tunnel enclosed by warp threads, is omitted, as the warp threads are fed onto the open legs of the V from the left and right sides using two warp yarn picks. This shed, which is open at the top, makes it possible to place almost any material between the warp threads. For example, a conveyor belt can drop materials into it. The usual weft insertion methods are no longer necessary at this point.

Of course, a counter shed must also be formed. To do this, the warp yarn sheaves fed in from the side cross over the V-shed and now form one of the usual tunnel-like sheds into which a weft is inserted, e.g. with a rapier. This open V-shed is thus formed at every second shed and then fixed with a conventional shed formation. This shed technology can also be combined with complex weave constructions such as a two-ply fabric, which forms the V-shed between two woven plies in order to insert a filling material directly on the weaving machine.