29/02/2016 — auf Deutsch lesen

The digitalisation drive

LEDs in wall textiles with illuminated arrows indicating the nearest escape route in the event of fire; RFID labels “hidden” in the fabric, clearly labelling branded goods and making the lives of counterfeiters that little bit more uncomfortable: Applications such as these will be easier to realise thanks to the preparatory work conducted by PASTA (Platform for Advanced Smart Textile Applications).

At the outset, the EU project, an R&D network comprising 13 companies from 5 countries, had set its sights on developing and making available beyond national borders a range of new technologies for the low-cost mass production of smart textiles. After running for four years, the project has now drawn to a successful close. Dr. Klaus Jansen, Managing Director of the Forschungskuratorium Textil research body, the umbrella association of the 16 German textile research institutes, pointed out: “EU projects such as PASTA strengthen cross-border cooperation in important research fields.” Even though, as he said, Germany plays a pioneering role in technical textiles, he underlined the key role of the many experts throughout Europe, who supported and helped progress the European textile and apparel industry by contributing their specialist knowledge.

Participating in PASTA from Germany was the Saxon Textile Research Institute (STFI). The Chemnitz-based engineers succeeded in working a metal yarn fitted with semi-conductors into textile lengths with large surface areas, using standard processing methods on embroidery and knitting machines – a prerequisite for the large-scale functionalisation of textiles with electronics.

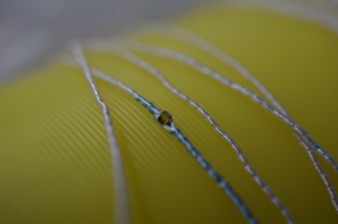

“We used a composites machine from Karl Mayer Malimo,” explains Dr. Heike Illing-Günther, Head of Research at the STFI. “It’s equipped with an innovative weft insertion system that allows the weft insertion of high-strength fibres such as carbon. We found, however, that we were also able to include electronically functionalised threads.” The conductive thread, also known as E-Thread, was supplied by Primo 1 D, based in Grenoble, who was also a partner of PASTA. The metal thread can be functionalised in a special process with tiny components such as LEDs, all without conventional wiring (bonding). The conductor can be used not only for the current supply but also as an antenna – see RFID labelling – or a data bus.

An elastic connector enables the integrated electronics to be wired, let us say, to a rechargeable battery, both safely and in a way that is in keeping with the fabric’s specific properties. The “interposer”, which is protected from moisture by a synthetic material, is designed with meander-shaped contacts which stretch or contract when exposed to mechanical loads and stresses. A module of this kind can be affixed to a textile and connected up to the E-Threads. Another new development emerging from the project are“Crimp Flat Packs”, micro-chips or sensors on special copper mounting frames.

To integrate them in the textile current circuit, their contacts and the conductive thread are pressed together mechanically. A self-learning robotic system with vacuum grippers is used that is designed for high production rates and which moves independently on four axes. It also has a camera eye and is capable of localising the optimum contact points along the E-threads in the textile and of placing the components in the right spots.

The PASTA project gave rise to a whole series of application scenarios. They reflect a full spectrum of possible applications, with everything from LEDs in protective clothing for the rescue services to smart bed sheets for hospitals with moisture and pressure sensors and intelligent textiles for the non-destructive monitoring of load-bearing composite components. A sensor textile from Ettlin AG, for example, measures the forces arising in prosthetic legs for the purpose of enhanced fitting. Smart textiles are also suitable for adjustable heating elements in car seats.

“With the research and technology transfer taking place within the framework of PASTA, we’ve seen how intelligent textile products can trigger many new applications in the health, lifestyle, safety and automotive fields,” states STFI’s Head of Research Dr Illing-Günther. “They provide the innovative forces in the textile industry with the tools they need to assert and strengthen their leading position on the global market and to produce timely applications for series production.”