18/08/2022 – Insulation — auf Deutsch lesen

Effective insulation combined with minimal space

Under the name Aersulate, the Outlast R&D team developed highly innovative aerogel materials offering very effective insulation with minimal space requirements.

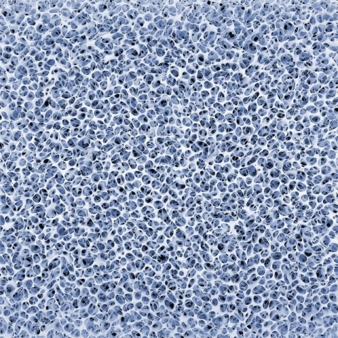

Aerogel, already successfully used by NASA, is made of Quartz, the base material of sand. It has a distinctive pore structure with an air content of around 98%, making it the lightest solid in the world. This high air content and the typical microporous struc-ture are the ideal prerequisites for highly functional insulation materials.

Based on extensive research and development, Outlast has succeeded in permanently bonding aerogel to textile substrates in high concentrations, without affecting the original properties of the textile or modifying subsequent processing procedures, leading to excellent insulating performances.

When comparing identical non-woven substrates with and without Aersulate technology, Outlast achieves an increase in thermal resistance of up to 100% which is hardly effected when compressed or when exposed to humidity. At the same time, it is very breathable, highly hydrophobic and can be equipped with additional FR properties when requested. Characteristic for the Aersulate textiles is their low thickness at highest performance. While conventional insulation materials usually achieve their functionality through increased thickness, Aersulate products are space miracles. Materials as thin as 1-2 mm can provide excellent insulation. This offers completely new potentials, whether in the classic consumer goods sector, in technical applications or in the security and construction sector.

Aerogel used in Aersulate is produced in Germany and is harmless to health and environment. The Aersulate product range is “Made in Germany”, guaranteeing the highest environmental and safety production standards.