26/10/2023 – Dilo Group

Innovative needlefelt technologies for more sustainability

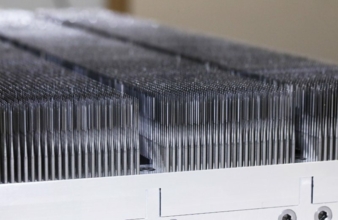

The general reputation of needling remained rather low among experts for many years, according to Dilo. Irrespective of this, however, numerous further and new development efforts in textile machinery and plant engineering with quality improvements in the end product and considerable productivity increases have made needling technology a highly modern and sustainable production technique.

However, in the recent past, needlepunch production has been surpassed by hydroentanglement, due to its dominance in hygiene and medical applications. Due to the importance of the ecological demands of sustainability, the latest development of Dilo`s “Micro Punch” intensive needling technology now offers the potential for a further increase in the applicability of needlefelt technology, especially in the field of nonwovens for hygiene and medicine, but also in technical applications in the automotive industry or in clothing technology, where needlefelt fabrics are now finding their way into textile surfaces, currently related to sports and outdoor applications. Here, too, a circle is closed by the fact that the mechanical reprocessing of needled nonwovens is foreseeably easier, i. e. less energy-intensive, compared with fabric waste.

The Dilo Group, through its new partnership with the specialists Dell'Orco & Villani for modern tearing technology and with Techno Plants as a specialist for aerodynamic web formation of torn spunbonded fabrics, has the complete portfolio as a general contractor for the recycling of fibrous materials. For the areas of “post consumer” and “post production”, solutions are available in a wide variety of plant designs for so-called “clean hard waste recycling” for spinning or nonwoven applications in all stages of different capacity and quality. Here, the so-called controlled tearing plays an important role, if too large reductions of the staple length in the tearing process are to be avoided. Naturally, there is also a correlation between quality and throughput, where fiber-conserving tearing naturally also has lower throughputs than in a tearing mill without regard to length losses.

You can read the complete article in the next print edition of textile network.