14/08/2020 – Seamless round woven geotextiles — auf Deutsch lesen

vombaur: Safe and efficient drainage

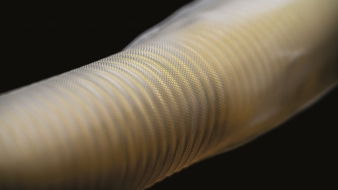

Woven geotextiles have high tensile strength and their flow rate can be precisely controlled by the choice of weaving technique.

Textiles are indispensable in the construction industry: geotextiles stabilise the soil, protect against erosion, filter, and drain. Drainage is generally used to protect buildings or agricultural land from waterlogging. Textile filling tubulars are regularly used for this purpose. The tubulars are filled with minerals and – temporarily or permanently depending on the requirements – sunk in shafts or construction pits, where they absorb the moisture and thus ensure the drainage of the terrain.

Heavy load, tough requirements

Geotextiles need to comply with extremely tough requirements. The tubulars must prevent the penetration of soil particles into the interior of the tubular while at the same time being sufficiently water permeable to absorb the moisture. They are permanently exposed to moisture and have to withstand considerable physical forces – from the soil on the outside and from the minerals inside.

No seam, no undesirable breakage points

This explains why civil engineers often use seamless woven filling tubulars: because woven geotextiles have high tensile strength and their flow rate can be precisely controlled by the choice of weaving technique. And because seamless round woven tubulars have no fabrication seam in the longitudinal direction, vombaur filling tubulars are extremely stable and durable. After all, the longitudinal seam is a particular weak point in fabricated geotextiles.

High-performance textiles from your development partner

As a development partner, vombaur selects the raw material, material type and weaving technique for each project to reflect the actual mechanical, chemical and thermal requirements. Because not all geotextiles are the same. A filling tubular for a bridge construction project in southern Spain has to meet different requirements than a drainage tubular as part of a dyke construction project on the North Sea coast. This is why vombaur uses different synthetic and metallic yarns in its woven tubulars, depending on the application, but always high-performance materials – for seamless drainage solutions.

Indestructible: Seamless round woven geotextiles by vombaur

High load-bearing capacity

High cut resistance

High burst strength

Uniform shrinkage behaviour

Uniform material thickness – also on curvatures and edges

Uniform flow rate

No undesirable breakage points due to seam or weld contours in longitudinal direction

Long service life and low wear

vombaur – Specialists for seamless round woven narrow textiles

vombaur is a specialist for seamless round woven narrow textiles and known throughout the industry as a development partner for filtration textiles, composite textiles and industrial textiles made of high-performance fibres. Technical narrow textiles by vombaur are used on the one hand for filtration – including in the food and chemical industries. They are used as high-performance composite materials in aircraft construction or medical technology, for example. For technical applications, vombaur develops specially coated industrial textiles for insulation, reinforcement or for transport in a wide variety of industrial processes – from precision mechanics to the construction industry. The company from Wuppertal, Germany, founded in 1805, currently employs 80 staff. For 2020, a turnover of more than €10 million is expected. Export turnover is at 44 percent.