27/09/2023 – vombaur

The eco-friendly game changer

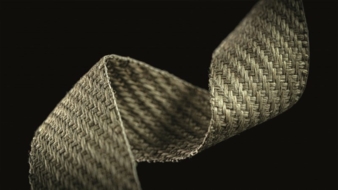

The combination of high strength and rigidity with sustainability and a neutral carbon footprint makes flax the ideal raw material for natural fibre-reinforced plastics. Vombaur offers composite textiles made of this natural fibre for the automotive, wind power, construction or sports industries and many other sectors.

Flax fibers are natural materials with remarkable properties that have been harnessed by vombaur for various technical textile applications. These fibers are sturdy, tear-resistant, possess natural antibacterial qualities, and are virtually antistatic and stain-resistant. Historically, flax was widely used for textiles until cotton took over during the late 19th and 20th centuries. However, due to its eco-friendliness and regional availability in Europe, flax is regaining importance in textile and composite manufacturing.

Ideal mechanical properties and carbon footprint

Flax fibers excel in lightweight design due to their ideal mechanical properties, offering stability in natural fiber-reinforced plastics (NFRPs) while remaining lightweight. Thanks to their low density of 1.50 g/cm3, the fibres weigh virtually nothing. Additionally, NFRPs with flax fibers are less prone to splintering compared to glass fiber-reinforced plastics. Moreover, flax cultivation absorbs CO2, and NFRP production emits about one-third less CO2 than conventional fiber-reinforced plastics, contributing to resource conservation.

Sustainability without impacting on quality

Flax`s sustainability extends to recycling, as it can undergo more recycling cycles than glass or carbon fiber-reinforced plastics without quality degradation. Flax fiber tapes from vombaur have versatile applications, including high-performance sports orthoses, skis, automotive and aerospace components, wind turbines, and window profiles. Carl Mrusek, Chief Sales Officer at vombaur, explains: “After all, wherever flax tapes are used, three key properties come together: light weight, strength and sustainability.”

Properties of vombaur`s flax tape include width options, heat and splash water resistance, single grade, and biodegradability. Flax itself boasts a density of 1.50 g/cm3, modulus of elasticity ranging from 80 to 100 GPa, tensile strength of 1100 MPa, and an elongation at break of 2.0 to 3.0%.