19/01/2016 – direct-to-garment — auf Deutsch lesen

The market is growing

Of all the growing markets for digital print, the textile sector is proving to be among the fastest and, within that segment, direct-to-garment production is rapidly expanding in popularity. The trend for personalisation on apparel has led to significant take-up for systems that appeal to print-on-demand businesses, screen-printing and embroidery shops.

These join digital print specialists wanting to extend their services and a wealth of online suppliers that can set up operations for just-in-time production that offers low SKU and fast turnaround business models. The growth in demand for personalisation has been driven by end users who, increasingly, are aware of the presence of unique products and want to take advantage of owning and wearing customised clothing. As such, direct-to-garment printing now represents a significant portion of the printed textiles market, with $165billion of sales being achieved during 2014 using digital technology.

Although print devices have been in evidence for some years, the increase in popularity of digitally decorated garments has risen significantly now that stable, reliable and versatile devices using ink-jet technology have become available. These machines cater admirably for one-offs and short runs and are even available as an additional station for a screen-printing carousel or oval, thus bringing users the best of both worlds with mixed processes output onto the same garment.

Accelerated times from desktop to finished garment are now among the key drivers for generating new opportunities for businesses who want to offer the fast turnarounds demanded by todays end customers. These can be consumers as well as brands wanting to trial new designs and offer limited editions without incurring high set-up costs and waste. To address requirements, typical direct-to-garment print devices have now been developed to work in 24/7 production environments. These are complemented by start-up units that provide a cost-effective alternative to screen-printing or, at the lowest production level, heat transfer methods.

Typically, in the direct-to-garment segment, it is possible to invest in a low-end dye sublimation print device that can handle some applications, although these are limited in choice of material. However, for businesses wanting to extend beyond the restrictions of polyesters and mixes that have to be used with this type of ink, pigmented dyes offer far greater versatility. These enable virtually any material to be printed, with no pre- or post-treatment, and result in an eco-friendly solution and end product that matches many of the standards preferred today, including Oeko-Tex 100 and GOTS certification and approval.

Traditionally most printed garments, as well as roll textiles used for home furnishings and décor, have been generated using the screen process; tailored for higher volumes, also involves the use of chemicals, plus lengthy set-up and changeover times including post-print wash-down. Waste levels also tend to be high, and pollution at large print operations is becoming a growing problem because of the high amounts of water and energy required during post production. This principle also applies when reactive and acid dyes are used in digital printing machines as jobs also require significant pre- and post-treatment, including steaming and washing, as part of the finishing process.

Todays direct-to-garment printers offer a range of options, but the use of a pigmented ink brings additional benefits as well as the ability to use one type of dye for virtually all materials. These advantages mean that a business can run one machine or a series of units and know that the ink is suitable for all apparel being printed, making it easy to maintain an uninterrupted workflow. The NeoPigment process developed by Kornit Digital and incorporated into all of the companys devices also simplifies printing onto dark garments and the inclusion of white ink as part of the design. It is also clean and odour-free, generating vivid well-saturated results across all fabrics.

Certainly digital textile technology requires consistent and strong colours that stand the test of time, with apparel typically being subjected to the rigours of everyday life. Not only should the finished garments be scuff and scratch resistant, they must also be able to handle the demands of regular washing while maintaining a good “hand” or feel that is pleasant to touch. Kornit Digitals direct-to-garment systems are renowned for its NeoPigment process because it meets all of these criteria, with the company also applying the same principles within its high-speed industrial 1.8m fabric system, the Kornit Allegro.

Because of the relative simplicity of being able to produce high quality garments straight from the desktop, direct-to-garment technology has opened up new revenue streams for companies that want to work within a market segment where just-in-time ordering and stocking is simple. Demonstrating the true versatility of print-on-demand, this type of apparel printing, in conjunction with Kornits NeoPigment process, continues to extend the opportunities for start-up and existing print companies looking for additional revenue streams. The market for personalised garments is also huge and is set to increase as trends for customisation are set by consumers as well as by brands that want to run limited edition merchandise.

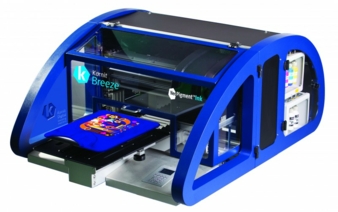

For Kornit Digital, the companys foresight into the future of direct-to-garment printing has resulted in a family of machines that caters for small companies through mid-sized to large organisations that want to reap all the benefits that are available with digitally produced apparel. There are solutions available that start with the Kornit Breeze, suitable for users as a start-up option before they move up the ladder and invest in a unit that accommodates high speeds and greater volumes. Kornits Avalanche series features models that incorporate discharge ink and additional colours for brand matching, sporting and promotional apparel that require ultra-vivid results, plus its work-horse Storm II which is engineered for speed and volume and is ideal in high-level production environments. Finally, Kornit Digitals Paradigm II shows how fine quality four-colour half-tones can be incorporated into a design to be printed using the screen process, combining analogue and digital print.

As the emphasis for digital versatility continues, so Kornit Digital has addressed fabric market demands to bring its NeoPigment process to additional market segments. The Kornit Allegro simplifies roll-to-roll fabric printing in a single-step solution that removes the need for external process steps, resulting in the fastest cycle times possible. Finally, the newly announced Kornit Vulcan advanced direct-to-garment platform aims to satisfy businesses that need to produce up to 250 high quality garments per hour, with both light and dark garments being throughput at the same speed.

For businesses wanting to add direct-to-garment printing to their production capabilities, the choices available are becoming more diverse as technologies continue to be developed for this exciting and thriving market arena. But the key questions to consider prior to make the first step include ease of use, return on investment, versatility across all fabrics, environmental factors, colour fidelity and ink formulation and, of course, a manufacturer that understands the past, the present and the future of this fast-growing segment.

[Oliver Lüdtke]