29/04/2015 — auf Deutsch lesen

Hohenstein: Graphene goes textile

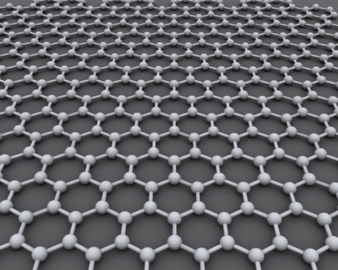

A wonder material sets new standards: Graphene is a single layer of carbon just one atom thick, in the form of a honeycomb lattice made up of hexagons. This layer, just a few nanometres thick, can only be seen under a scanning tunnelling microscope and holds within it the technology of tomorrow.

The material is multifunctional: ultra-thin and therefore transparent, an extremely efficient conductor of electricity and heat, with higher tensile strength than steel, yet flexible and abrasion-resistant and impermeable to gases.

These outstanding properties of graphene mean that it has many potential uses in industry. While research is making rapid progress especially in the field of conductivity, the use of graphene in the textile sector has so far been somewhat overlooked. This is where a research project run by scientists at the Hohenstein Institut für Textilinnovation gGmbH in Bönnigheim, in partnership with the companies Iolitec Ionic Liquids Technologies GmbH from Heilbronn and Fuchshuber Technotex GmbH from Lichtenstein, and Belgian project partners Centexbel and Soieries Elite, comes in. The team led by Project Manager Dr. Roshan Paul is working within the EU research funding programme "M-era.Net" on the German sub-project called "GRAFAT – Using graphene for the surface modification of textiles in heat protective clothing" (sponsorship ID 03X0157A).

"Over the next three years, the consortium will be investigating to what extent the surface of textiles can be changed using graphene modifications, in particular with a view to later applying the process to heat protective clothing. Graphene has all kinds of positive properties which would revolutionise this sector. This research makes us world leaders in using graphene modification on textile surfaces," says Dr. Paul. The transformation of the various graphene modifications into stable aqueous dispersions is being carried out by Iolitec.

The aim of the Hohenstein research team is to develop stable techniques for applying aqueous graphene dispersions, so that they can be used as a permanent coating on different textile surfaces. A range of different graphene modifications (e.g. graphene oxide, "multi-layer graphene") are being considered, since they each have different properties. The newly developed surface modifications for the various textiles will then be analysed for their suitability for heat protective equipment.

In the research work, the company Fuchshuber Technotex has the task of converting the application formula that has been developed to an industrial scale and ensuring that the treated textiles can be cleaned and processed. The aim is to produce a demonstrator model. Using graphene to modify the surface can significantly improve the flame-retardant properties of a textile. Graphene can act as a physical barrier, effectively preventing the penetration of heat and gases. At the same time, graphene also has the potential to prevent the thermal decomposition of the textile. Another benefit of graphene is its resistance to abrasion and rupture, about 200 times higher than that of steel. These qualities also make graphene extremely interesting for applications in the field of personal protective equipment.

Normally, the functionalisation of textiles for PPE requires a multi-stage process. This may no longer be necessary if graphene can be applied in a single-stage process. The material used for PPE could then be thinner and therefore lighter. This in turn increases the wearer's mobility. "If their functionality can be successfully proven, textiles with graphene-modified surfaces could find many uses in the PPE sector, especially in heat protective clothing," says Dr. Paul. This would open up a new market segment for the use of graphene, further enhancing the economic success of innovative companies and the industry in general.

Graphene is a layer of pure carbon, just one atom thick. A distinction is made between single-layer and multi-layer graphene and graphene with more than 10 layers, which is called graphite (pencil lead). Even though the structure is the same, the different numbers of layers result in different properties.

A graphene layer is about 0.3 nanometres thick, just one hundred-thousandth of the thickness of a human hair. Each carbon atom in the layer is bonded to three more carbon atoms, creating a two-dimensional honeycomb-like layered structure.

Graphene and oxygen can be converted into graphene oxide which can contain different amounts of bound oxygen. By linking or functionalising it with other molecules or atoms, different chemical properties can be produced in the material.