20/02/2023 – Finishing machines — auf Deutsch lesen

Effective measures for reducing energy consumption

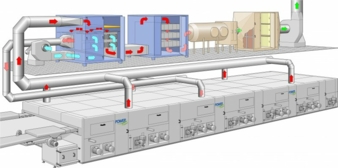

Brückner presents effective measures for reducing energy consumption and purifying exhaust air on textile finishing machines.

Consumption and exhaust air purification are more in focus today than ever before, due to rapidly rising energy costs and prescribed emission limits. Brückner offers systems that can be retrofitted to third-party lines and contribute to a more sustainable and resource-saving production, according to the company.

By using a heat-recovery system high energy efficiency is achieved. The “Eco-Heat“ heat-recovery system air/air or air/water uses the exhaust air heat of the production lines for heating fresh air or water. Integrated steam cleaning, while not 100% clean, keeps the heat exchangers operational for an extended period of time. After some time, deposits form on the heat exchangers. Every few weeks, the heat exchanger modules must be replaced for cleaning. They can be cleaned in an ultrasonic cleaning bath and can be used again immediately.

The “Eco-Air” products are a modular system for the compliance with existing exhaust air regulations. The “Eco-Air“ exhaust air scrubber for example cools down the exhaust air further and binds oil-containing pollutants in its closed water circuit. After this, an “Eco-Air” electrostatic precipitator can ensure that even the finest aerosols are separated from the exhaust air after the exhaust air scrubber. This also causes the visible smoke above the outside chimney to disappear and the exhaust air odor to be reduced to a minimum.

Brückner offers additional bio-filters which is cost-effective method of cleaning exhaust air containing odorous substances and VOCs. Organic molecule chains can also be broken down in a UV light reactor by intensive UV light irradiation of the exhaust air, and oxygen can be converted into active ozone. In this way, as in the bio-filter, odours and VOC concentration in the exhaust air can be minimized.