11/03/2020 – New benchmarks in the production of nonwovens — auf Deutsch lesen

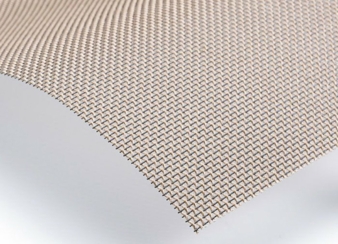

Innovative glass hybrid fabric belts from GKD

The innovative belt construction from GKD, is an energy-efficient lightweight in dryer operation and significantly increases process efficiency.

After more than three years of practical application, the results have significantly exceeded the high expectations: In exacting thermal bonding processes, the innovative glass hybrid fabric belts from GKD – Gebr. Kufferath AG (GKD) offer impressive process performance and product quality. More and more users are now choosing this type of belt which was initially predominantly used as a magnetic upper belt in double-belt dryers as well as a lower belt. Its completely PFA-coated construction of glass strands in the running direction and metal wires in the weft prevents adhesions of adhesive products. This minimizes cleaning intervals and downtimes, while the production speed and tool life far exceed conventional benchmarks.

Weighing just 1.8 kg per sqm, this innovative belt construction from the leading international technical weavers GKD, is an energy-efficient lightweight in dryer operation. At the same time, the material combination of metal and fiberglass significantly increases process efficiency thanks to its highly resistant PFA-coating. Even when using BiCo fibers, it reliably protects the wires and the intersections between the chain and weft against adhesions. Neither fibers nor binders are deposited in the fiberglass strands or between the wires. This minimized soiling means production speeds can be significantly increased. The high transverse stability of this type of belt is crucial in optimizing the process quality and product quality: Even for products with large weaving widths or strong shrinkage forces, the single-ply belt construction impresses thanks to its excellent running properties. In the upper belt, magnetic steel weft wires, which are over 0.8 mm thick, reliably hold the belt on the magnetic strips. The resulting absolute flatness guarantees exact calibration and compression. When used as a lower belt, a stainless steel weft wire guarantees similar transverse stability. Even highly voluminous and significantly compacted products obtain a constant thickness and density over the entire width, with minimal tolerances.

Years of runtime for the upper and lower belt

Glass hybrid belts by GKD are characterized by an even mesh opening with high air permeability. The fiberglass strands are temperature resistant up to 250 °C, thus preventing belt elongation. In addition, the intricate PTFE edge coating also makes the belts more durable: This very smooth and absolutely straight cut edge makes reliable belt control easier. Furthermore, the sewn, non-marking pin seam guarantees impression-free production of nonwovens. The growing demand for use as the upper and lower belt is a striking reflection of all the advantages of GKD glass hybrid belts. Initially installed by plant manufacturers as the upper belt in dryers, these belts have been running since 2016 and have far exceeded the expectations of the first users. Compared to glass gauze belts, which often only last for a few months in wide thermal bonding plants, the years of runtime provided by glass hybrid belts have compensated for the higher procurement price several times over during the first year alone. The result is that more and more users have installed this type of belt as the lower belt too, where it has been running with great success for about a year and a half. So, overall, GKD’s glass hybrid belts have proven their worth as a sustainable, economic solution for thermal bonding processes due to their durability, increased productivity, minimized cleaning intervals and higher production speeds – with better product quality to boot.