08/01/2024 – Trends supply chain management

19th Hermes Barometer: digital technologies are of crucial importance

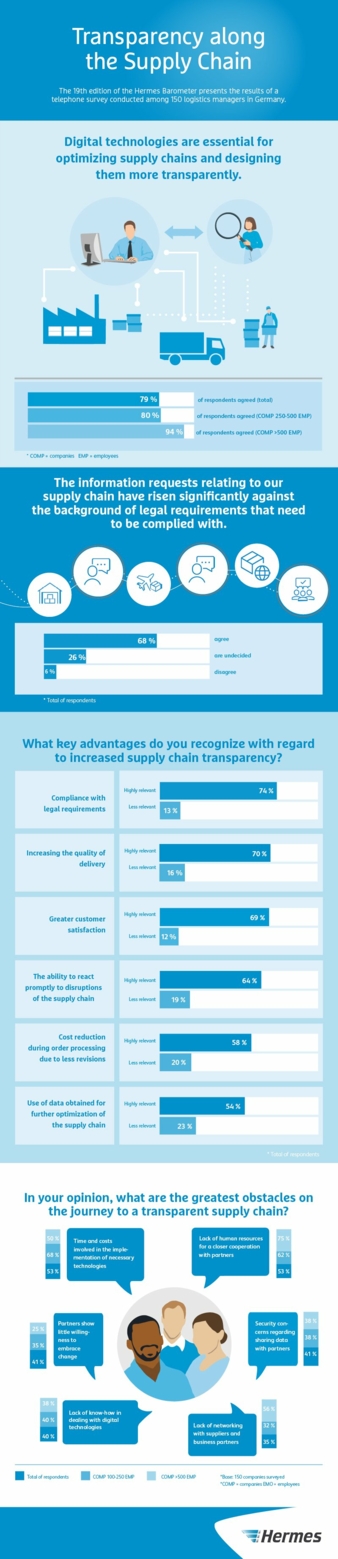

Digital technologies should make a decisive contribution to increasing supply chain transparency, as the survey for the 19th Hermes Barometer “Transparency along the Supply Chain” revealed.

Transparency is also required with regard to sustainability: in view of the scarcity of resources and increasing legal requirements, companies must not only ensure compliance with ethical and ecological standards along their supply chain, but they must but they must also be held accountable for it.

Sustainable supply chain through transparency

At 57%, more than half of the companies surveyed therefore attach importance to data collection and analysis in order to reduce risks and comply with the environmental and social standards required by law. “Transparency replaces unawareness and is key to creating sustainable and responsible supply chains,” confirms Nadja Grabenströer, Division Manager Sales & Corporate Functions at Hermes International, a division of Hermes Germany. “Successful supply chain management should therefore always include transparent and detailed traceability as well as AI-driven data monitoring. In this way, companies can monitor and optimize their CO2 emissions holistically and also support downstream supply chain partners with targeted measures.”

Faster response

In addition to compliance with sustainability criteria, the logistics managers surveyed find further advantages connected to a transparent supply chain. The majority of survey participants agree that a detailed insight into the individual supply chain processes can help to improve the quality of deliveries. Across all company sizes, 70% of survey participants view this factor as a key benefit of transparency, as it gives them better control over the delivery process and enables them to identify potential bottlenecks and problems at an early stage. 75% of larger companies with more than 500 employees also value the improved ability to react to unforeseen events, which they believe goes hand in hand with increased supply chain transparency. “In order to proactively counteract possible risks, a constant data exchange and increased cooperation within the supply chain pay off. The end-to-end synchronization of logistics and production enables companies to react more quickly and efficiently to disruptions, bottlenecks, or challenges,” Nadja Grabenströer comments on the survey results.

Need to exploit potential

Optimized data flows and process-related real-time mapping increase the opportunities to benefit other parties in the supply chain – most companies are aware of the enormous potential that comes with advancing digitalization and transparency. And yet, the 19th Hermes Barometer also reveals: More than half of all companies polled (58%) do not yet have a digital real-time supply chain. Only one in five logistics managers surveyed (20%) agree that they have already implemented appropriate measures to digitally map all processes and identify risk factors along the supply chain.Furthermore, only a few of the companies surveyed already use collaborative platforms, AI or the Internet of Things. Based on the information provided, there is still potential for optimization, especially when it comes to implementing the technologies. “Digital technologies play a key role in making complex supply chain processes and collaboration with partners and suppliers transparent and mapping them in real time. However, incompatible IT systems and data formats can make it difficult to merge information,” says Nadja Grabenströer. “The advancing digitalization already offers smart solutions for this challenge: SCM platforms, for example, provide valuable insights with data-based analyses, identify obstacles and improve the agility of your own supply chain. Companies now have many opportunities to increase transparency along their supply chain.”

Further information on supply chain visibility, logistics and SCM in the Hermes Supply Chain Blog can be found here.

About the survey

Participants: 150 logistics managers

Method: telephone survey

Survey period: October 2023