02/08/2024 – Upgraded “TSA” device — auf Deutsch lesen

Driving sustainability in the textile chain with “TSA”

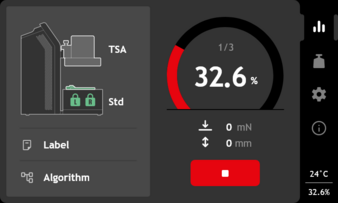

Emtec Electronic, a leading German manufacturer of specialized testing equipment for the paper, textile, and nonwoven industries, has launched an upgraded version of its “Tactile Sensation Analyzer (TSA)”. This innovative device offers a robust solution for improving logistics, supply chain management, and sustainability in textile production.

By providing objective, digital test data to assess haptic quality, the “TSA” significantly reduces the need for physical sample shipments and enhances control over production processes, leading to a more efficient and environmentally friendly textile chain. As the textile industry evolves, tools like the “TSA” will play a crucial role in driving sustainable practices and ensuring high-quality production standards.

Enhancing sustainability and efficiency

Traditionally, assessing the haptic quality of textiles involves subjective hand testing, which is prone to variability and inaccuracies. This often necessitates extensive testing and repeated sample shipments between stakeholders in different geographical locations, notably between brands and apparel companies in the US and Europe and producers in Asia. The “TSA” device addresses this challenge by providing objective data on the intricate nuances of touch. Beyond assessing softness, smoothness, and stretch and recovery parameters within a mere two minutes, the upgraded device evaluates additional parameters such as thermo-haptic, friction, and crumple or drape behavior. This digital approach guarantees clear and consistent communication of haptic specifications throughout the supply chain. Brands can verify haptic compliance with manufacturers without repeatedly shipping physical samples. This ensures that only necessary samples are produced and shipped, thereby reducing courier costs, minimizing environmental impact, and enhancing overall efficiency.

Improved quality assurance and communication

The enhanced “TSA” now features a built-in high-resolution camera that captures detailed images of fabric structure and weave, making optical analysis easier. This data can be digitized and shared through the “Virtual Haptic Library”, a cloud-based platform created in partnership with Black Swan Textiles. The library organizes “TSA” data based on specific haptic and optical characteristics and is accessible worldwide, allowing for quality control and assurance regardless of location. It also functions as an online marketplace, streamlining the process of locating, comparing, and replicating samples with specific haptic requirements, thereby improving communication and efficiency throughout the supply chain.

When the “TSA” data is uploaded to the cloud, customers can access haptic data from anywhere in the world. This promotes transparency and allows for prompt intervention in cases of deviations from agreed-upon haptic parameters, reducing the number of rejected batches and streamlining the production process, ultimately leading to greater waste reduction.