04/12/2025 – Technological advances in warp knitting — auf Deutsch lesen

Karl Mayer: 35 years of EL technology

From the first trials with electric motors to the latest innovations presented at ITMA 2023, EL technology has shaped machine development at Karl Mayer for 35 years.

Electronic control transforms warp knitting

On 30 November 1990, Karl Mayer delivered the first warp knitting machine featuring electronic guide bar control, the KS 4 EL. This model opened a new chapter in patterning, allowing data-based operation without mechanical restrictions. Running up to 37 percent faster than machines equipped with the SU drive, it also required less maintenance and space while providing complete patterning flexibility.

From the SU drive to the EL system

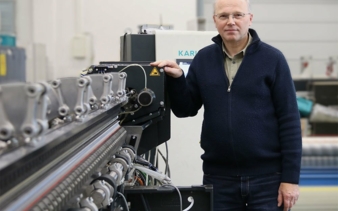

As early as 1980, Karl Mayer paved the way for digital patterning with the introduction of the SU drive. By controlling the shogging motion magneto-mechanically via actuators and a microcomputer, the system offered virtually unlimited repeat lengths and significantly reduced setup times. The transition to electric motors in the following decade lifted these developments to a new level. "We wanted to use electric motors to move the bars. That was completely new territory," recalls Georg Kraus, who was involved in the project from the outset.

Expansion and new applications

After its use in tricot machines, the EL system was extended to other machine types, including double and lace raschel machines as well as models for technical textiles. In 2002, Karl Mayer introduced the TL 66 – the first multibar raschel machine with electronic control of all guide bars. Later, the company applied the same principle to additional process components. The Advanced Feeding Control (AFC) regulates yarn feeding and ensures stable performance even in the case of complex patterns.

Looking ahead

With solutions such as the vario-weft system for weft insertion machines, Karl Mayer continues to explore new possibilities in pattern formation beyond conventional mechanics. The EL principle remains a foundation for greater efficiency, flexibility and digital integration in warp knitting.