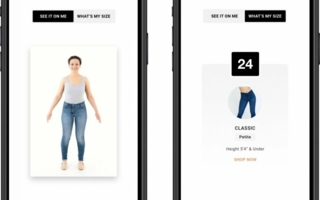

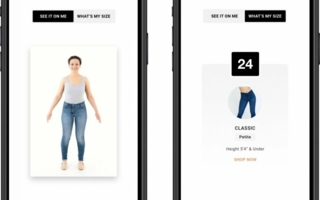

Brands that use YourFit have decreased return rates by up to 48%, while increasing conversion by four times year over year. © 3DLook

Brands that use YourFit have decreased return rates by up to 48%, while increasing conversion by four times year over year. © 3DLook

Truetzschler presents its broad range of CP products optimized for specific requirements. © Trützschler

The Oerlikon Nonwoven Meltblown technology offers a cost-efficient solution for the production of high-quality meltblown nonwovens. © Oerlikon

With the new Verglas Infinity shell outdoor clothing from Helly Hansen, hikers are well equipped for a long trip in the mountains. © Helly Hansen

Mimaki’s newest LED-UV large format flatbed inkjet printer, the JFX600-2513, made its debut at the Mimaki Innovation Days event. © Mimaki

The mechanical recycling process enables the re-use of blended fibers from old clothes, in form of high-quality yarns. © Imat-uve