12/04/2016 – Research — auf Deutsch lesen

Best digital textile printing

The aim of the research project by ITCF Denkendorf, DITF-MR and TITV Greiz is to establish a reliable data basis for pretreatment when using inkjet printing. The idea is to find better integration between substrate and ink through a series of laboratory experiments.

For this purpose the ITCF characterizes printing ink of various compositions by means of their physical parameters such as surface tension, viscosity and wetting behavior and prints them on textiles that have been pretreated in various ways. The impregnation is chemically modified in such a way as to achieve together with the printing ink and textile that is used, the optimum wetting properties.

The capillary rise method is used as the method of measurement: fabric is dipped into a watery dye solution. Over a period of time observations are made in regards to what extent the watery solvent and dye spread onto the textile. This method offers evidence in regards to the affinity of dyes to specific textile materials and in regards to hydrophilicity and wetting speed.

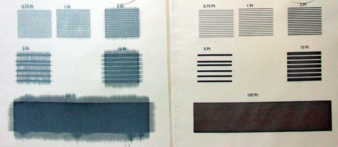

The results can be correlated with the print resolution and reliably demonstrate in which way a pretreatment should be carried out in order to prepare a specific textile for printing in the best possible way.

Methods of measurement supported by images reveal information in regards to the wetting kinetic of individual ink drops and allow detailed understanding of how even minimal changes affect the ink formulation and composition of the pretreatment (impregnation).

Finally, the measurements obtained in the laboratory should be summarized in a data base. With this, it should be possible to consistently ascertain the ideal combination of ink, pretreatment and textile – for reproducible user results.