11/05/2021 – Advert — auf Deutsch lesen

Technical Textiles, Circular-Knitted, Please!

Circular-knitted fabric is versatile, both in classical and in technical textile uses. Circular-knitted technical textiles are used, for example, as a carrier material for coatings or as technical textiles in their own right.

“Nearly a fifth of the circular knitting machines in our portfolio regularly knit technical textiles,” says Jürgen Müller, head of the pattern service at circular knitting machine manufacturer Mayer & Cie. Medical textiles, home textiles (including mattress covers) and seat covers for cars, buses, trains and trams are circular-knitted. The latter are subjected to extremely heavy wear and must be resistant to abrasion and comply with operators’ pattern specifications. Plush machines like the MCPE 2.4 and the MPU 1.6 E are a popular choice for knitting fabrics of this kind. For car seats, the Relanit 1.6 E is another favourite.

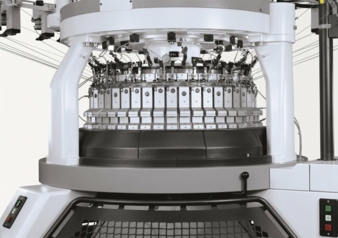

The Relanit 0.8 is a circular knitting machine specially developed for technical use. Instead of cotton it processes glass fibre, silver and aramid yarns along with metallic yarns in different alloys. Fabrics of this kind are at home in the environmental sector, used in filters and catalytic converters and as seals or shielding fabrics. Aramid fibres provide stab and cut protection and are used in personal protective equipment.

Circular-knitted carrier materials: spacers, artificial fibres and smart functions

In the technical sector, Jürgen Müller adds, artificial fibres are mainly used, and conceivably in the widest range of combinations. The Technit D3, for example, knits spacer fabrics with up to three threads on the front. Fine rib fabrics can also be knitted with three threads in a stitch course. “That,” says Jürgen Müller, “provides scope for innovative uses. A functional thread of, say, metal can be plated on the basic thread, thereby creating an electrically conductive surface, conceivably for seat heating.”

Other standard machine types for spacer fabrics are the OVJA 1.6 E, the OVJA 1.6 EE 3/2WT, the OV 3.2 QCe and the D4 2.2 II, which knits high-quality spacer fabrics up to E32 gauge. All these machines provide the basis for a wide range of carrier materials.