16/11/2018 – Jumbo-Textil — auf Deutsch lesen

Intelligent and individual

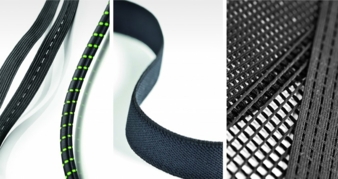

Whether strips, braids, cords, nets – products from Jumbo-Textil turn up and support us all over the world!

For example, elastic and non-elastic ribbons and strands by Jumbo-Textil keep the interior of vehicles tidy and enhance safety – for example when storing smartphones and the like or securing luggage in the boot. In particularly skin-friendly designs, they provide a safe hold and flexibility for protective and functional textiles or medical products. Depending on the area of application, they have specific properties and are, for example, flame-retardant or salt water resistant.

Rubber ropes that reliably hold heavy loads on cranes, in gate technology or sports equipment. Fine cords that fix small, light objects in the paper industry or in the interiors of vehicles: cords by Jumbo-Textil ensure secure connections in all sizes and specifications.

Drones are sensitive aircraft. At an international race they were caught and braked by Jumbo nets. After all: “Only the Jumbo nets perfectly met our extraordinary, highly demanding specifications in terms of durability, material and structure,” explained John Messner, CEO of IWX Messner GmbH, which was responsible for technology at the event. Also in the SolarCar by the Bochum University of Applied Sciences a net by Jumbo-Textil fulfilled all requirements – during a race lasting several days across Australia with interior temperatures of 40 to 50°C. In buses, elastic nets made in Sprockhövel ensure the safety of passengers and the future security of the operators: the bus nets already comply with the new UN fire protection regulation UN ECE-R118 for new vehicles, which will apply from 2020.

Highly demanding specifications

The requirements for narrow textiles in the different industries are as varied as the products with which Jumbo-Textil responds to this diversity. The teams develop individual solutions in close coordination with the customers. They are produced on a total of 7,500 square meters at the company headquarters in Sprockhövel. More than 20 million metres of high-quality narrow textiles are produced on innovative braiding, knitting and weaving machines every year: narrow textiles that impress with their high load-bearing capacity, first-class quality, colour and fitting accuracy – and reliably offer precisely the properties that they should possess. “Jumbo-Textil is more than a manufacturer of high-quality textiles," emphasises Andreas Kielholz, managing partner of Jumbo-Textil. “We are an innovative partner for high-tech narrow textiles.”

Jumbo-Textil was founded in 1909 in Wuppertal. At that time it was a manufacturer of narrow fabrics, cords and string. Today, which is headquartered in Sprockhövel, employs some 65 staff. The elastic specialist is known throughout the industry as a manufacturer and developer of high-tech narrow fabrics. For 2018, a turnover of approx. EUR 12 million is expected. Export turnover is at more than 50 percent.