20/04/2021 – Vombaur — auf Deutsch lesen

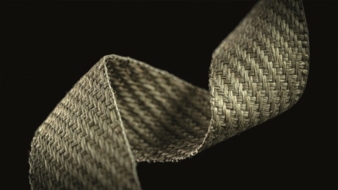

Sustainability: Woven tapes made of natural fibres

With woven tapes made of flax, Vombaur makes the functional and ecological advantages of natural fibres available for lightweight design.

Flax fibres are particularly rigid and tear-proof. Textiles made of the natural material therefore give natural fibre reinforced plastic (NFP) special stability. Additionally, flax has a low density. The components thus combine high rigidity and strength with low weight.

Another functional plus: natural fibre reinforced plastics are less prone to splintering than glass fibre reinforced plastics.

Sustainable material

The cultivation of flax binds CO2 and the production of NFP generates 33 percent lower CO2 emissions than conventional fibre reinforced plastics. The energy consumption is 40 percent lower. This reduces production costs and improves the material's CO2 footprint. Punch-packing arguments for natural fibre tapes – like flax tape by Vombaur – in lightweight design applications.

Circular Economy

Circular Economy – this also works in lightweight design. The number of recycling cycles without loss of quality is higher for natural fibre reinforced plastics than for glass or carbon fibre reinforced plastics: the thermoplastic matrix of the composite can be melted and recycled after a product life cycle. The natural fibres can “live on” in other products – injection moulded products for example.

Tomislav Josipovic, Sales Manager Vombaur:

“Composites from our flax tapes are used to reinforce high-tech skis as well as for extruding state-of-the-art window sections – the applications are countless. As a development partner, we support applications for the automotive, wind energy, construction, sports and many other industries with our composite textiles.”

Vombaur is a specialist for seamless round woven narrow textiles and known throughout the industry as a development partner for filtration textiles, composite textiles and industrial textiles made of high-performance fibres. Technical narrow textiles by Vombaur are used on the one hand for filtration – including in the food and chemical industries. They are used as high-performance composite materials in aircraft construction or medical technology, for example. For technical applications, Vombaur develops specially coated industrial textiles for insulation, reinforcement or for transport in a wide variety of industrial processes – from precision mechanics to the construction industry. The company from Wuppertal, Germany, founded in 1805, currently employs 80 staff. For 2020, a turnover of more than 10 million euro is expected. Export turnover is at 44 percent.