29/11/2018 – ITA/RWTH Aachen — auf Deutsch lesen

Textile in space

The Institut für Textiltechnik Aachen (ITA) of RWTH Aachen University has successfully launched its Aerospace engineering and Manufacturing program.

The program is focussed on developing low cost, high quality solutions for aircraft engine components, aircraft parts manufacturing and metal matrix composites for aerospace applications. These have been undertaken through 6 EU, international and public funded projects. ITA’s latest Space Systems development initiative has now been launched with the new Space-Reflector project.

As a part of this initiative, ITA and its partner Large Space Structures GmbH (LSS) based out of Munich will develop advanced communication satellite systems. ITA’s role will primarily be focussed on the development of the reflector surface mesh structure which lies at the heart of these advanced communication satellite systems. Growing internet consumption requires advanced satellite reflectors to meet the high bandwidth and transmission needs.

Space-Reflector project

Dynamic geopolitical scenarios influence technology policy, in particular communication policy, in the regions in which telecommunication service providers are allowed to offer communications satellite services. For example, for security-sensitive regions such as Syria and the neighbouring regions, nationwide telecommunications are required. This can be achieved by either launching a dedicated satellite for the region or by using ITA’s proposed technology of providing a morphable (shape changing reflector surface) antenna that can be individually adapted to a specific region based on the operating mission requirements.

In order to reconcile the diameter of a reflector of up to 30 meters and the maximum transport size of 4.5 meters, the reflectors must be foldable. The reflectors being developed will transfer high operating frequencies sent from and to earth. These individually adaptable satellites, based on the operating mission requirements, will result in the reduction of the overall number of satellite deployments and hence operational costs by up to 20 percent for the end customer.

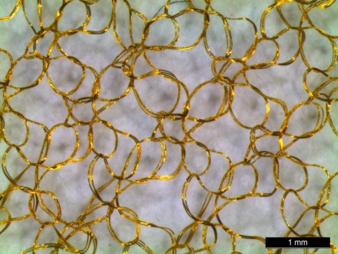

In order to produce these next-generation satellite reflector surfaces, a textile technology based approach will be utilized. The approach will combine design and manufacturing techniques clubbed with advanced materials that have not been researched till date. A combination of advanced materials such as gold plated tungsten, Polyether Ether Ketone (PEEK), Aramid etc. will be evaluated for the production of these reflectors.

Partner firm LSS

The partner firm LSS bring its expertise in design, and satellite structure development to this project. LSS focusses on creation of large deployable space reflectors and other large space lightweight structures, as well as in-orbit mechanically reconfigurable reflectors. While ITA focusses on producing the mesh structure for the antenna reflector, LSS will help develop a functional surface for the reflector using a combination of advanced materials and processes.

The goal is to perform the development and production of these reflectors and carry out preliminary mechanical and electrical tests as a part of this Space-Reflector project.

“Space-Reflector” commences in October 2018 and will be completed in March 2021. The first space environment and launch ready prototypes are expected to be available from 2023.