16/04/2019 – Techtextil: Fraunhofer ITWM — auf Deutsch lesen

Designing polymer spin packs in line with dynamic flow

Simulation and optimization methods to support customers in the development, design and improvement of spinning packages.

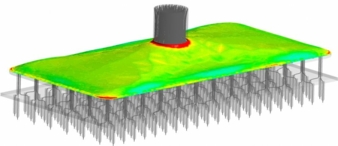

Spinneret and spin packs are used in the production of synthetic fibres and non-wovens. The spin pack is a metal block comprising internal cavities and fine channels through which the polymer melt is forced. The molten polymer is channelled through a tube into the spin pack. Arriving in the first cavity, the molten polymer distributes itself across the entire width of the pack. It passes through several layers of filters, held by a support plate, before it is spun through the fine capillaries in the spinneret plate. This results in fibres that are either wound into yarns or laid into non-wovens. The Fraunhofer ITWM simulates flow in the spin pack, whilst taking account of the specific displacement and flow behaviour of polymers. With the help of special tools, both dwell periods and pressure flows are evaluated.

The analysis indicates which components of the spin pack need to be improved.

Fraunhofer Institute for Industrial Mathematics (ITWM)

Techtextil

Hall 3.0 C76