06/03/2017 – Textile Innovations from Chemnitz — auf Deutsch lesen

Index 2017: STFI

Das Sächsische Textilforschungsinstitut e.V. shows at index 2017 the following innovations.

Multiway surgical textiles of functional layers with specific requirements

Multiway surgical textiles (surgical gowns, surgical cover sheets) for high-performance use were developed in a research project by STFI in cooperation with VOWALON Beschichtung GmbH in Treuen (Germany). These textiles are characterized by Trilaminates. They are designed by nonwovens arranged as top and bottom layer and an inside layer made of a high-performance polyurethane membrane which is permeable to water. The developed material complies with all protective requirements. Moreover, this material presents optimized properties of skin sensory and wear comfort.

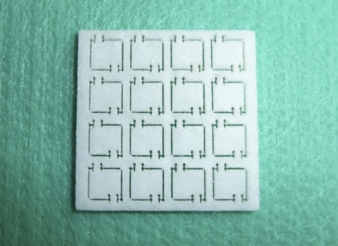

Thermoelectric generator

In cooperation with the University of Dresden, the STFI is developing a printable voluminous structural nonwoven for the use in thermoelectric generators (TEGs). These generators can convert partial process waste heat directly into electrical energy, which can be fed back to the technical process again.

The STFI is developing the voluminous nonwoven fabric, which gets soaked by a thermoelectric polymer. The thickness of the nonwoven material thereby decisively determines the height of the thermopair. The TU Dresden is developing the conductive printing pastes and the application technology. The aim is to provide curved surfaces e.g. pipes with a TEG-nonwoven fabric and for generating new application fields which cannot be covered by currently known TEGs. A first TEG-pattern is shown at the STFI booth No. 1369.

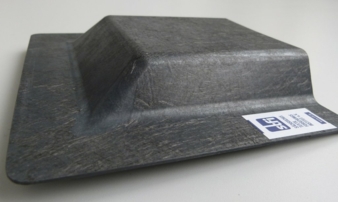

Support layers for adhesive tapes for cable sheathing

Nonwoven adhesive tapes, based on textile composite constructions, fulfill all requirements for a support layer for adhesive tapes. They are temperature and media-resistant, rot-proof, non-toxic, pliant, hand-tearabe and reach the sound isolations class C, according to LV 312-1.

Nonwoven adhesive tapes can be produced in various dimensions. The research object was already transferred into production.

Nonwovens made of carbon fiber recycling material

Carbon nonwovens for textile lightweight construction are shown. The STFI developed a process line for the use of dry carbon fiber recycling material which is first processed into torn fibers. The fibers then will be further processed with the carding and/or the airlay technology to fiber bonded or overstitched nonwovens.

Textile Filter

Applications for classical filter fabrics were enhanced with filter made of nonwovens or fabric-nonwoven combinations. Besides the well-known drylaid and wetlaid nonwovens, needle punched nonwovens or bonding agents, spunlaced nonwovens, filament and fine fiber nonwovens as well as airlaid nonwovens have been established. Membranes and nonwovens made of nanofibers, manufactured with different web forming processes complete the product portfolio.

Filter media developed at STFI are HYCOSPUN® , HYCOFIL® and HYCOKNIT® - hydrodynamically designed and uniform multilayer composites (purely mechanical, without bonding agents) with functional layout for air filtration (pocket filters, filter bags, filter cartridges) and liquid filtration (filter cartridges). Corresponding samples are issued at the STFI booth.

Meet us at booth No. 1369