17/06/2019 – ITMA: Zünd — auf Deutsch lesen

Advanced technology in digital cutting automation

The textile industry is in the midst of a digital transformation with value chains that are becoming increasingly interconnected.

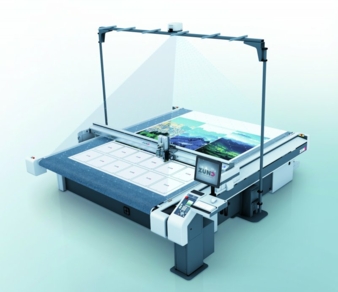

In a digital chain, automated cutting constitutes an important link. At ITMA, Zünd presents efficient, high-performance automated cutting workflows with state-of-the art software tools that illustrate the breadth of its digital know-how.

As in so many other industries, digital technology has long since taken hold in the textile industry. Consumers are demanding individualized offerings and flexible solutions, tailor-made clothing and furnishings to measure – all at “off-the-rack” pricing. Design and configuration options are increasingly diverse as manufacturers become more agile and faster to cope with increasing market pressures and ever-shorter product life cycles. To accomplish all this, however, manufacturers need appropriate production processes.

Zünd is exhibiting state-of-the-art digital cutting systems with comprehensive production workflows that cover everything from pattern matching to projection-supported removal of cut parts. Integrated, intelligent, digital – from start to finish.

With the Over Cutter Camera OCC and its advanced optical system, cutting patterned and digitally printed fabrics is just as precise and easy as cutting non-printed or solid-colored textiles. The OCC captures all register marks at once. If no register marks are available, the Over Cutter Camera can determine the position of the printed image by capturing a corresponding outline that was printed along with it. The system can also automatically detect patterns and any material distortions that may have occurred. When compensating for distortions, the system perfectly maintains dimensional accuracy of the cut parts and their correct position on patterned fabric. Based on reference points, the software also automatically determines the most efficient parts layout and nesting. Cutting, pattern matching, and nesting occur simultaneously to ensure uninterrupted processing. And in a final step, a projection system facilitates the removal of cut parts.

Zünd at the ITMA, Barcelona

Hall 3, stand B 227