10/05/2021 – Corona — auf Deutsch lesen

Weko: Innovative spray-finishing against infections

With the non-contact Weko application system, there is considerable potential for savings with regard to the use of resources.

Weitmann & Konrad (Weko) with its headquarters near Stuttgart / Germany, develops and produces concepts and systems for the non-contact minimum application with rotary atomizers which focus on sustainability.

Based on this principle, Weko fluid application systems are used worldwide for non-contact moistening/conditioning and finishing of continuously moving webs in minimum application processes. Today, in addition to the nonwovens industry, the areas of application include many others such as the textile, tissue, paper, wood fibre board and plastics industries.

Worldwide pandemic of Covid-19 is raising the demand of specialized and individual products to fight microbial, viral or bacterial impact and diversity of finishings is growing. Future products will be added with those functions in much more industrial sections than today – not only in medical and hygenic industry. More flexibility in production is required while consumption of chemicals, water and heat energy becomes a bigger point in terms of sustainability and optimizing the margins.

In times of increasingly scarce resources, sustainability has become a central topic in the nonwovens industry. Finally, the finishing should be as material and resource-saving as possible, yet effective.

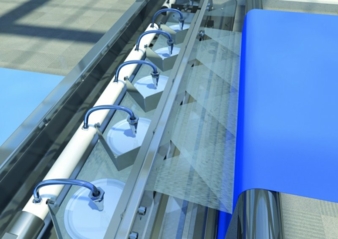

Principle of the non-contact Weko application system:

The fluid is supplied to the center of fast rotating discs which speeds it up and distributing it by centrifugal force to the disc edge. Liquid threads are built which are separated to an even 360° stream of micro droplets by overcoming the cohesive forces. Special covers creating precise spraying windows. To reach the needed spray format several rotor discs are installed beside each other in Weko rotor carrier.

Furthermore, the spray application is not bound to the wetting of a roller. This allows formulations to be more concentrated and prepared with less water, provided that the wetting effect corresponds to the desired goal. Due to different line configurations, application to the web on one or both sides or equipping each side with different functions is possible.

Potential savings potentials result from the use of

water up to 70 per cent

use of additives up to 60 per cent

drying energy up to 90 per cent

Weko-ProTec: high efficient antimicrobial finishing of nonwoven or technical textiles

The encapsulated version Weko-ProTec provides the rotor carrier with an enclosure and connects it to an extraction system. Contamination of the working environment is thus counteracted. This is particularly advantageous when using oil or silicone-based fluids. Substances which have been excluded from rotary atomizers for health reasons can also be used more often with this variant for example antimicrobial, antiviral or antibacterial finishing. In the in-house Weko pilot lane, many trials outside of the running production chain can be tested in advance in order to guarantee customers the greatest possible flexibility and to enable their own test series outside of the production.