3D Printing

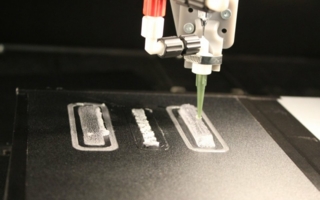

Demonstration samples - In order to obtain reproducible results and to be able to predict the deformation effects, the possibilities for defined stretching of the textiles were investigated. © STFI / Dirk Hanus

13/12/2024 – Research project

Research project

TechStyle Fabric Alignment Station, the next milestone in the evolution of Stratasys 3D Fashion-technology. © Stratasys

29/10/2024 – 3D printing

3D printing

“I wouldn’t be able to achieve such complicated geometric designs without the Stratasys 3DFashion technology, as attaining this level of symmetry by hand would simply be impossible,” explains Hefetz. © Stav Peretz

21/06/2023 – 3D Technology

3D Technology

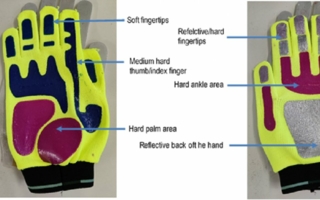

The 3D printing process was used to produce printed sock and glove samples that were equipped with several functional modifications in a single process step. © STFI

16/11/2022 – Several functional modifications in a single process step

Several functional modifications in a single process step

In the project 3DNaturDruck, construction elements will be manufactured additively from natural fibers, such as here a free-form tile made of wood short fiber filament. © LZH