28.10.24 – Textile printing

Mimaki's “Trapis” ushers in a sustainable future

For decades, polyester has been the cornerstone of the textile printing industry. Its compatibility with the digital sublimation process – a cost-effective, simple technology – has driven exponential growth in polyester printing.

However, the very characteristics that make polyester well suited for sublimation printing render this printing technique unsuitable for other materials, such as cotton and some blended fibres, leaving a significant gap in the market. This gap was, until recently, partially filled by direct-to-textile printing. This method requires substantial initial investments in equipment and heavily relies on the time- and resource consuming pre- and post-processing of fabrics to ensure colourfastness, colour accuracy, and compatibility with different substrates. Consequently, a need arose for a more sustainable and cost-effective solution that could cater to a wider range of textiles.

Bridging the gap: the birth of “Trapis”

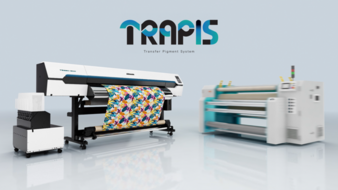

In response to this demand, Mimaki spent six years developing a breakthrough technology, “Trapis”, a simple two-step textile transfer printing solution, consisting of only an inkjet printer and a high-pressure calender. The design of choice is printed by the inkjet printer onto the company’s groundbreaking Texcol pigment ink transfer paper. This is then transferred to the application via the calender. This technology gives printers the ability to print on a wide variety of materials, including natural fibres like cotton and silk without losing stretchability or colourfastness.

A bright future: the environmental benefits of “Trapis”

The pre-treatment and washing of the fabric is often needed in digital dye printing, producing a significant amount of wastewater in the process. “Trapis” eliminates those stages altogether and is almost entirely waterless, saving around 14.5 l per square metre of water, an almost 90% decrease in comparison to digital dye printing. (1)

Additionally, this eliminates the need for wastewater treatment facilities, which can be both expensive and constrictive when it comes to where the solution is installed. When you consider that traditional dyeing processes generate a staggering approximately 2 billion tonnes of wastewater every day from pre- and post-dyeing processes worldwide (2).

Offering a simple solution

“Trapi's” simplicity and affordability also make it ideal for localised, short-run textile production. As the process only involves printing and transferring, it does not require specialised skills to operate when compared to the more complex seven- or eight-step system needed by most digital and analogue conventional printing. The lack of a fabric conveyor belt in the system further minimises the need for time-intensive maintenance.

(1) According to Mimaki’s original research, digital dye printing generates significant amount of wastewater by textile printing conveyor belt washing and fabric washing after dye fixation (steam)

(2) Based on Mimaki’s own research