04/01/2022 – The Inventor’s Dilemma – The Entrepreneur’s Responsibility

Looking Back Ahead: In Dialog with David J. Gerber – Part III

With their third online session between Connecticut in the US and Brussels on the European side of the pond, David Gerber and Yvonne Heinen-Foudeh addressed the aspect of education and training, gaps in the eco-system to date, but above all the methodology to conceive and implement new approaches to solutions.

textile network: Would technical colleges and universities in the U.S. and beyond today offer the curricula that will produce the young talent that the digitally networked industry will need? It was Joe Gerber, who said: ‘Education is the wings on creativity’. What would he possibly have initiated and supported from Gerber in this urgent situation?

David J. Gerber: My father endowed scholarships personally and through his company. He was always grateful for his educational opportunities. He was a trustee of his alma mater, Rensselaer Polytechnic Institute, Troy, NY, and he emphasized the need for broad knowledge across technical and nontechnical disciplines in its curriculum and degree programs.

In today’s world especially, with the accelerating pace of advances in new technology, he would emphasize the ability to clearly communicate across technical and nontechnical fields. The schools can play such an important role in deepening the understanding of concepts so that managers, inventors, customers, and other stakeholders communicate meaningfully rather than on a superficial level using buzzwords.

In terms of apparel schools, Gerber Technology was an important donor of technology. My father recognized a business interest, since these schools trained the new generation of workers who were needed to run the computer-based tools. He also felt, as a supplier of automation technologies, an obligation to promote retraining of apparel workers for the industry’s new computer-based jobs.

textile network: Can you imagine that Joe Gerber, with his knowledge and experience, would have contributed to education as a teacher himself?

David J. Gerber: No, not as a professor. He was a do-er. He wanted to solve problems and put his ideas into practice. But he loved to see the spark of interest and imagination in young people and he enjoyed mentoring young engineers.

textile network: What demand would your father have taken up, thus continuing his work as an inventor and innovator, to respond today’s essential questions?

David J. Gerber: As an inventor, my father could be unpredictable. He found problems that had not been recognized as ‘problems’. He often looked for a totally new approach – not just adding computer controls to a machine or replicating human motions, but a new process.

His inventions ranged across many technologies, from metallurgy to optics, software to structures. Most of all, my father’s ideas were often simply very inventive. If I could predict the opportunities that he would have identified, I’d have an additional 200 patents to my name! (smiling)

textile network: You previously mentioned that your father had a ‘method’. Does this point to the directions of his innovation?

David J. Gerber: Yes. Looking at my father’s work as a whole, one can see patterns that predict or at least explain his inventive directions.

textile network: What were some of these patterns? I assume that he looked for solutions that related to existing products, industries, and capabilities at his company.

David J. Gerber: Yes, he did. As an inventor entrepreneur, he could choose the problems that he wanted to pursue but had to keep his business profitable. Sometimes, that meant improving or cost-reducing existing products.

One related pattern is that he invented systems, such as the automation system in the apparel industry. His early products for apparel design, marker making, and cutting structured this system in the 1970s. His company’s subsequent introductions improved these components, filled-in gaps, and integrated the system.

These advancements were all complementary, adding to the value of the whole system and each component and leveraging the company’s marketing relationships and service commitment to the industry.

textile network: What ‘gaps’ remain in this system?

David J. Gerber: Well, some examples could be the manual process of removing and bundling the stacks of cut parts, 2D/3D design and layout, and the integration of various textile operations. Perhaps, even fashion shows.

textile network: How would you propose to automate a fashion show?

David J. Gerber: The essence of my father’s approach was not to replicate or just improve how things have been done but to achieve the same ultimate goal, often in a new way that allows dramatic benefits. Imagine computer-generated figures, 3D glasses, and the ability to simulate drape, pattern, color, and environment. Would this achieve the goal of fashion shows? I don’t mean to suggest that I understand all the social and other functions provided by fashion shows. My purpose is just to illustrate the broader point about my father’s thinking. I’m sure Heidi Klum has nothing to fear from computers! (laughing)

textile network: What would your father think of the automation system for apparel today?

David J. Gerber: First, he would recognize today’s system as a march toward the ideal system he envisioned and set into motion in the 1970s and ‘80s. He would see new ways to move it further toward this ideal. For example, he might utilize increased computing power, new materials, or unexpected methods (such as applying static electricity to cloth pieces to solve materials handling issues at the root of assembly and pickup). Or, he might develop new methods that are so inexpensive that factories could be local and near to the merchandiser and market.

Then, he would look at how to change the system, not just by combining steps, but by finding new ways that obviate the need for the steps. For example, in the ‘80s, he investigated additive manufacturing, such as spraying flock on anthropomorphic molds to form clothes, and growing leather parts similar to how skin is grown for burn victims in Petri dishes, rather than cutting and assembling parts from stacks of fabric. Whatever he landed on, I am sure that he would start by finding opportunities to do some task better and thus create value for the customer in a way that hadn’t been apparent before.

textile network: David Gerber, thank you very much for the inspirational conversation!

The questions on behalf of textile network were asked by Yvonne Heinen-Foudeh.

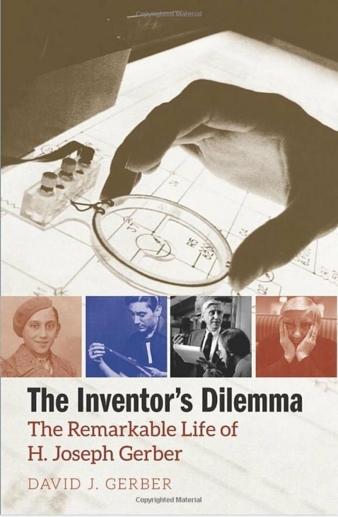

Joe Gerber – The Biography

David Gerber’s “The Inventor's Dilemma: The Remarkable Life of H. Joseph Gerber” (Yale University Press, 2016), which provides extensive sources, references, and visual material, is the biography of Heinz Joseph Gerber (April 17, 1924 – August 8, 1996) and a history of computer automation of manufacturing through the second half of the twentieth century. The book describes Gerber’s leadership in inventing, developing, and commercializing factory automation systems across the landscape of manufacturing, from the origins of engineering design, drafting, and graphics, through the products of our daily lives: vehicle, electronics, books, shoes, signs, eyeglasses, and most notably, textiles and apparel.

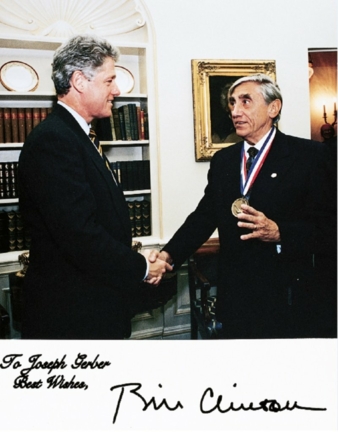

For apparel and textiles alone, the National Academy of Sciences observed in 1994 that “For nearly a quarter of a century, Mr. Gerber [has] made exceptional technological contributions that rank among the milestones in the history of the textile industry.” In addition, continuous innovation, integration of software and hardware, and worldwide implementation of technological innovation for design and manufacturing of textiles and apparel characterize his life’s work – with impacts that have continue right up to the present day.

Joe Gerber’s personal life, as remarkable as his professional achievements, is also described as he, in his youth, survives and escapes from Nazi Austria in 1940 and makes his way in America as an immigrant by studying and working at a grueling pace, and his creative spirit and talent for invention already manifest themselves.

David Gerber’s work provides deep insights into his father's holistic way of thinking and working and shows how he managed the worldwide industrial implementation of his system developments. The history of the company empire with a worldwide sales and service network is also traced – from the 1947 founding of the Gerber Scientific Instrument Co., through the formations of its subsidiaries, each focused on a respective industry, including the 1969 formation of the Gerber Garment Technology (renamed Gerber Technology Inc. in 1995), through the evolution of the parent company, Gerber Scientific, Inc., which was first listed on the New York Stock Exchange in 1980 and had annualized sales that would reach a half billion dollars.

- Gerber Technology LLC was purchased by the French competitor Lectra SA with effect from June 2021, making the combined entity the world market leader in integrated automation systems for clothing, automotive interiors, upholstered furniture production, and processing of technical textiles. Gerber Technology is now part of the Lectra Company group with headquarters in Paris.