03/11/2016 – Quality assurance throughout the textile chain – Part 5 — auf Deutsch lesen

QA and logistics – how do they work together?

Quality is often associated more with the (manufactured) product. But it includes all of the activities throughout the length of the supply chain.

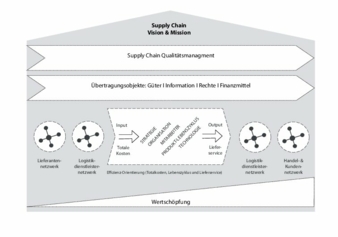

The purpose of the supply chain, and the logistical processes and structures integrated into it, is above all to ensure availability. Production does the knitting, the weaving, the cutting and the sewing. Supply chain management ensures that items sitting ready at the sewing machine, for example, are collected, packed, bundled, warehoused, stacked and transported. The flow of goods is planned, managed and checked by means of a parallel flow of information and is linked to the flow of rights and payment streams that are triggered thereby.

Supply chain processes create value!

Contrary to much popular opinion, therefore, supply chain processes very clearly create value. Only if the right product arrives at the right time, in the right condition, at the right place and at the right price with the right information is it actually ‘worth something’. Products that do not arrive or arrive too late (e.g. items that ‘are held up in customs’, when the fashion show is happening this evening) simply do not generate any value (they were too late on site and thus utterly without value for their purpose).

An illustrative example: A hypothetical example in practiceCEO: “We urgently need a process right now so that we can finally assess all our supply chain quality data and risks worldwide. Disasters such as those caused by the miserable supply quality of the Indonesian supplier must never happen again!” The Despatch Manager, who a year ago was perhaps re-designated the Corporate Supply Chain Leader, is expected to carry the can, make urgent changes and give a presentation to the next management conference. Unfortunately, no budget is available for this in the foreseeable future. The available staff are swamped. Cooperation from purchasing, production, development, finance and sales is limited, or is paid no more than lip service. The Supply Chain Leader quickly disappears from sight. It is not long before the next major bout of turbulence strikes the supply chain. Customers are lost.

Our author Prof. Dr. rer. pol. Stephan L.K. Freichel

Prof. Freichel is Professor of Distribution Logistics at TH Köln University of Applied Sciences and Visiting Lecturer at Hamburg University of Technology (TUHH). He acts as an independent consultant to well-known companies on issues of strategy and operational design of the value-added chain. A renowned expert in logistics and supply chain management, he has over 20 years’ experience in top management positions in industry, at GM, Merck, ZF and Microlog/Logwin, where he most recently spent eight years as chairman and director. Freichel was awarded the Prize for Logistical Science and badge of honour of the Federal Logistics Association e.V.