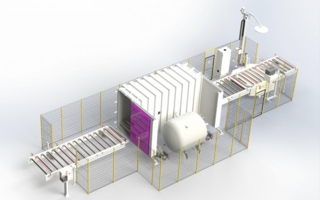

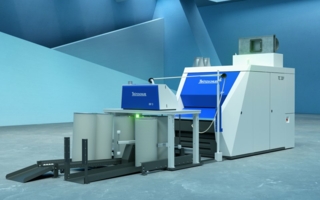

With the “IDF 3” customers benefit from better quality, higher efficiency and easier handling. © Trützschler

05/07/2023 – Spinning

Spinning

The Integrated Draw Frame third generation (“IDF 3”) was presented to visitors at the ITMA in Milan. The “IDF” has been part of the Trützschler portfolio ...