30/12/2021 – With foam to consistently high quality — auf Deutsch lesen

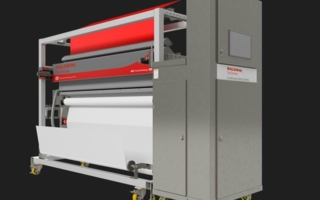

Foam generator for textile finishing

The system-optimised, dynamic foam generator ‘Eco-Mix’ is suitable for continuous foaming of pumpable and low to medium viscosity media from all areas.

Due to its high flexibility, the Eco-Mix can be used in almost all areas of the textile industry. The mixer can be found in the areas of textile finishing and textile refinement, e.g. the production of stain protection and anti-soil coating, of non-iron finishing, but also in filament consolidation with acrylates and PU dispersions. The use of foam offers the advantage of better penetration into the substrate with a constant, consistent quality over the entire working area.

Easy to use

At the same time, the Eco-Mix is individually adapted to the requirements of the respective production process with its system components. This is done with the help of the numerous variations of different mixing head sizes, as well as flow meters with different measuring principles. The required product quantities are the basis for the correct design of suitable pumps and air controllers. The sealing technology is variable and specially adapted to the type of product used, whether mechanical seal or static O-ring.

A programmable logic controller (PLC) in conjunction with a touch panel (HMI) make it easier for the plant operator to optimally adjust the individual process parameters. The control system in the Eco-Mix offers the user full control through automatic logging of all processes. Remote maintenance and software updates can be carried out quickly via the VPN connection of the integrated router to the customer’s network. Even though the mixer is virtually maintenance-free, the machine components can be quickly accessed by opening the doors or removing the cover panels, thus enabling visual inspection at any time.

Additional systems

The Eco-Mix is optionally available with various automatic systems that massively simplify the operation of the machine and at the same time guarantee consistent product quality. Quantity adjustment 1 (MA1), for example, offers the function that the foam generator automatically follows any change in the substrate speed in the system and there is always enough foam available for the process. Quantity adjustment 2 (MA2) also has a foam level control that continuously monitors the level in the foam supply and regulates it if necessary. If, for some reason, deviations do occur, all systems signal an optical and acoustic alarm.

At the end of each production run, or in the event of a product or colour change, the pumps, mixing head and all product lines in the Eco-Mix can be cleaned of product residues using a fully automatic and PLC-controlled CIP cleaning system, without having to open individual machine components or clean them manually. A colour change can be further simplified by optional dosing systems in front of or directly into the mixing head.