18/05/2016 – Mayer & Cie.: Spinit 3.0 — auf Deutsch lesen

The reinvention of knitting!

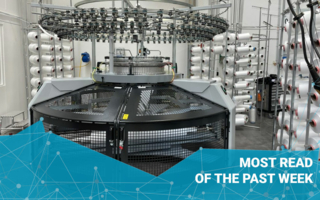

Spinitsystems, the new technology from Mayer & Cie., takes a truly unconventional approach to knitting.

In a nutshell, the spinning and knitting processes are combined, such that spinning, cleaning and knitting all take place inside one machine. This means that, for the first time ever, knitted goods are no longer made from yarn but from fibre rovings, rendering the rewinding process completely superfluous. At ITMA 2015, Mayer & Cie. celebrated the debut of its new, production-ready machine, the Spinit 3.0.

This innovative machine slashes the manufacturing time for single jersey knitwear. At the same time, it cuts investment costs whilst maintaining output, as fewer machines are needed. This, in turn, leads to space and energy-savings. Yarn inventories can be reduced, waste levels cut and production costs minimised.

The innovative “3-in-1 concept” allows the fibre roving to be fed directly into the machine where it undergoes a false-twist spinning process. A positive side effect of this procedure is that the fabric will not skew. Dr. Wolfgang Bauer, Head of R&D at Mayer & Cie., describes the most important developments on the machine as follows: “The drive technology had to be adapted to the requirements of spin-knitting. The breakthrough came in the past couple of years with the development of our Fancy Module, enabling us to vary the yarn count during the production process. The Spinit allows us to create really innovative patterns.” Perhaps the biggest obstacle to be overcome in the development phase involved the cleaning of the roving. This achievement led to a patent application. The compact build and easy operation of the Spinit 3.0. have great appeal. The modular design means that the modules are easy to attach and remove. The patented cleaning system eradicates irregularities and allows quality to be defined with precision. The machine operators will, however, need to adapt to the new system which transforms knitting or spinning experts into spin-knitting specialists.

At ITMA 2015 in Milan, the Spinit 3.0 was presented in a separate room, and not just because it requires a special spinning environment. The response from the industry was huge. “We had around 600 company enquiries and up to 90 visitors viewing the machine every day, including a whole host of potential customers, from fully integrated companies through to spinning mills,” concluded Michael A. Tuschak, Sales & Marketing. “We sold several machines during the fair which we will be delivering in the course of this year.”

Machine with great potential

Mayer & Cie. firmly believes the Spinit 3.0 has a great future, not only in traditional textile markets, but also in countries whose wage costs are high. Michael A. Tuschak: “A lot of cotton is grown in the US. The Spinit 3.0. means that cotton processing costs can be cut whilst opening the door to new kinds of knitted fabrics. This technology conceals a lot of hidden potential for our industry. Besides the usual single jersey applications, such as T-shirts, tops and underwear etc., technical applications are also possible, for example, as substrates for coatings.”

Looking to the future, the company’s innovation plans will focus on the further development of the Fancy technology and the expansion of processing options.