The newly developed Smart Energy Monitoring software solution can be used to determine and optimize the energy consumption of each individual axis per cycle. © Baumüller

05/12/2022 – Smart Energy Monitoring

Smart Energy Monitoring

The founders of Nahtlos AG José Näf and Michel Schmid with the textile-based electrodes for long-term ECGs in their laboratory in St. Gallen. © Marlies Thurnheer

09/11/2022

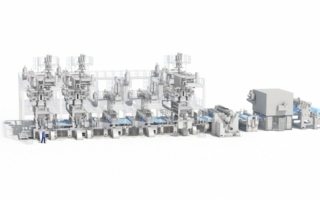

The latest machine generation RF5 sets benchmarks in terms of quality, performance, availability, efficiency, and machine intelligence. © Reifenhäuser

29/09/2022 – Nonwovens

Nonwovens

The fibers are pressed through spinning nozzles. The nozzles are located at the upper end of the spinning shaft of the plant. © Fraunhofer ITWM

05/09/2022 – Virtual spinning

Virtual spinning

So far, the circular strategy has mainly been applied to recycled fibres. In the future, it is expected that the textile finishing market will also follow this trend to a greater extent. © vegefox.com/stock.adobe.com