12/04/2019 – Techtextil: Lenzing Instruments — auf Deutsch lesen

High-end quality- and process control

Lenzing Instruments presents sophisticated quality assurance measurement systems for producers of filament yarn, staple fiber, nonwoven and woven textiles.

Customers are offered solutions for various automatization requests, including laboratory testing equipment, at-line high volume testing instruments together with online monitoring systems.

Systems for online process control

In line with the proceeding digitalization of the textile industry, Lenzing Instruments team of highly experienced specialists focuses on continuous development of systems for online process control.

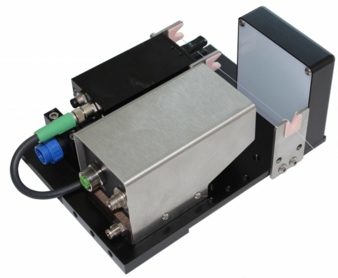

Optimized online and real-time crimp control of staple fiber is guaranteed by the new generation of Lenzing Instruments Crimp Inspection System, CIS 300. State-of-the-art image processing technology enables monitoring of a huge amount of single fibers for the crimp distribution along and across the moving fiber tow. Results can be traced back to specific bale ID’s and are given as average crimp count (counts/cm), long crimp, micro crimp and crimp distribution. The new intuitive and flexible software, higher image frequency and the enhanced possibilities for monitoring fibers of a wider colour range characterize the new CIS 300, which is one of the exhibits at the Techtextil.

For online and real-time process control of filament yarn

Lenzing Instruments customers appreciate the high reliability of the Prompt sensor technology. In combination with the sophisticated Prompt software program, the Prompt sensors offer continuous monitoring of defects and vital yarn characteristics. For detection of defects such as broken filaments, fluff, thin- and thick places as well as for control of yarn diameter, interlace and yarn breaks, Prompt OLO or Prompt FFD is the choice. Prompt OLT gives feedback about the yarn tension and based on conductive technology, the Prompt OLF sensor yields information about the spin finish content of the passing yarn. Real-time performance information by means of remote access to measurement results allows for quick reactions to process malfunctions. An even more thorough analysis of detected defects is offered by Defect View and Fray View: These two systems combine Prompt OLO respectively Prompt FFD with a high resolution camera, which generates images of detected broken filaments, fluff etc.

For quick checks of the spin finish content on one single spinning end, the hand-held sensor Opumeter provides fast and clear information about the momentary OPU/FOY content on the running filament yarn.

Lenzing Instruments (Member of Textechno Group) at the Techtextil

Hall 3.1, stand A39