10/12/2024 – Sustainable chemistry in textile finishing — auf Deutsch lesen

Polyethylene dispersion from sugar cane

One promising approach to reducing the carbon footprint on textile finishing is the CHT Group’s latest development of bio-based polyethylene dispersions made from sugar cane molasses which are more climate-friendly and meet technical requirements.

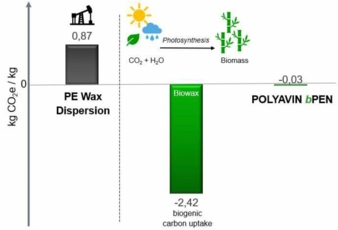

Polyethylene is used in many different ways in textile finishing, but is usually based on fossil sources with high CO2 emissions. Sugar cane molasses, a by-product of sugar production, offers an environmentally friendly alternative. The use of bioethanol as sugar cane molasses as a pre-product for polyethylene production enables almost climate-neutral production. These bio-based polyethylene dispersions can be used as a plug-in solution and offer an ecological alternative.

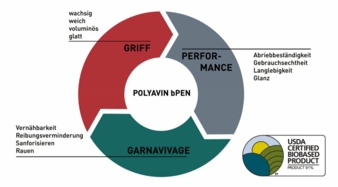

With Polyavin bPen, CHT offers a solution that replaces fossil raw materials and has a positive carbon footprint. The USDA-certified product consists of 91% bio-based carbon (according to ASTM D6866-22) and binds more CO2 than it releases. POLYAVIN bPEN can be used without compromising on quality and offers versatile added value in textile finishing.

Possible applications

Polyavin bPen is a versatile textile auxiliary. It supports uniform raising effects, reduces yarn friction and minimizes sewing damage. It supports shrinking processes such as sanforizing and improves tear and abrasion resistance, making it ideal for hard-wearing and durable textiles. In combination with calendering processes, it produces a high-quality, glossy surface.

With its property profile, Polyavin bPen offers the textile industry many advantages. It gives textiles a bulky feel, is highly compatible and supports the durability of textiles. These properties make Polyavin bPen technically and economically attractive, as it meets the growing demands of environmentally conscious consumers. Bio-based polyethylene dispersions such as Polyavin bPen are a step towards sustainable chemistry.