06/02/2023 – Circular Economy in the automotive industry — auf Deutsch lesen

Tool supports the development of recyclable components

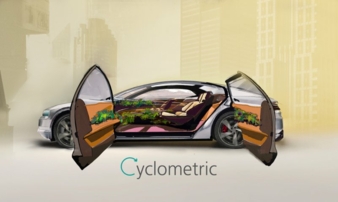

The Cyclometric tool is designed to ensure that all parts used are recyclable already during the development of automotive components.

Automotive components no longer only have to meet the highest technological standards, they also have to be sustainable and recyclable. In the future, engineers will not only be required to keep an eye on the final product during development, but also on its end of life. The German Institutes of Textile and Fiber Research Denkendorf (DITF) are one of the project partners in the Cyclometric research project, which is funded by the German Federal Ministry of Education and Research (BMBF) and supervised by the Project Management Agency Karlsruhe (PTKA). A tool is being developed that makes suggestions for improvement even during product planning.

Considering the end from the beginning

Recycling of high-performance materials often fails because the materials cannot be separated into their original components. Cyclometric aims to ensure that this problem does not have to be solved at the end of a product’s life cycle. With current methods and tools, environmental impacts are often not examined until near the end of development or even after production has begun – even though the most relevant decisions about product properties are made much earlier. The new system helps to make the right decisions during development. To this end, data, information and knowledge are analyzed and evaluated across all development phases and interfaces. Research approaches from advanced systems engineering and model-based systems engineering are used in conjunction with life cycle assessment methods and business model analysis.

Product developers juggle complex parameters such as producibility, recyclability, reusability, CO2 emissions and costs on a daily basis. Last but not least, the expectations and habits of customers have to be taken into account. Whether selecting materials or planning production steps, the tool calculates the impact and makes suggestions for improvement.

More than just automotive

In the Cyclometric project, a center console trim serves as an application example for the digital tool. It is made of sustainable textile materials and has smart functions integrated into the textile. Nevertheless, the finished tool is not limited to the automotive industry. It can be used in all industrial fields.

The DITF’s task is to select and test suitable materials. The team develops the appropriate manufacturing and processing procedures and creates a prototype. Test runs on the functional, everyday-, long-term and extreme suitability of the textile structures and fiber composites are carried out at the test laboratories, which can be reproduced in subsequent applications. Concepts for sensors and actuators are being developed for the smart functions of the console.

After completion of the project, the Denkendorf researchers will advise companies on how textiles can be increasingly used in vehicle interiors.