06/08/2021 – Self-healing with bioceramic — auf Deutsch lesen

Implants for bone defects

In this research project, scientists look at the use of ceramic hollow filaments as a filling and build-up substance for bone defects.

In recent years, a change has begun in biomedicine: Instead of classical, non-degradable and thus durable implant materials, bioresorbable materials are increasingly used which allow defect regeneration and support the body in self-healing.

In the case of bone defects, calcium phosphate bioceramics are advantageous because their chemical composition is close to the mineral phase of the bone matrix – hydroxyapatite (HAP). Since bone tissue is highly anisotropic in structure, research is focused on the development of anisotropic bone substitute elements.

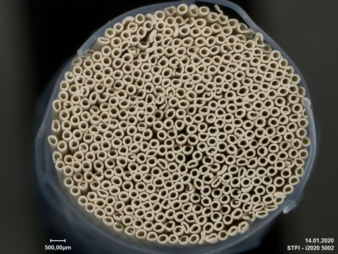

The focus is on variable-sized implants with pore structures that not only allow ingrowth of cells and tissue, but also access by blood capillaries. Such an implant is to be developed in this research project by means of textile technology processes.

The channel-like pores are produced via hollow fibers generated in a spinning process with additions of HAP and/or β-tricalcium phosphate powder. The suitability of polymer spinning processes for obtaining textile-like processable, stable hollow bodies in fiber form from cellulose and HAP and/or β-tricalcium phosphate is investigated.

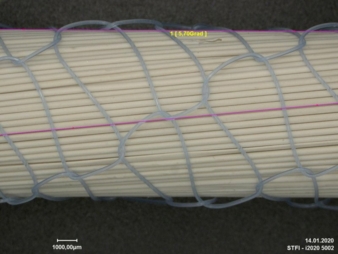

The macroscopic structuring and arrangement of the ceramic hollow fibers in the green state is achieved by means of orientation, sheathing and bundling with compact fibers. The Kemafil process is used for this purpose. In this way, the hollow fibers are combined into ideally dense packages and the longitudinal and transverse strength is decisively improved without closing the pores.

The fiber composite is then infiltrated to fill the fiber interstices, followed by a special drying, debinding and sintering process.

In the debinding process, the polymeric sheath yarn and the cellulose component of the fibers burn completely and without residue.

The sintering process serves to solidify the molded bodies into a mechanically stable and machinable bone substitute material with excellent biocompatibility at the same time.

After successful biological characterization and optimization of the final compacted calcium phosphate bioceramics and testing of their biocompatibility, the implants would be ready for in vivo use. This implant, produced by textile technology, can be used to fill a large bone defect and will be converted into endogenous material by the organism over time.

- The members of the team of the IGF-funded research project “Development of calcium phosphate bioceramics with anisotropic pore structure for tissue engineering using ceramic hollow filaments” work at TU Bergakademie Freiberg, Saxon Textile Research Institute e.V., Chemnitz, Thuringian Institute for Textile and Plastics Research e.V., and Dresden University of Technology.