31/07/2018 – Pfaff — auf Deutsch lesen

Process-reliable production with 3,200 s.p.m. sewing speed!

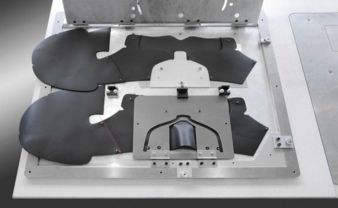

The Pfaff 3587 CNC-large-area computer stitcher with a sewing area of 500 x 300 mm offers high process reliability and production

At the core of the stitching automat is the intermitting material feed system featuring a patented drive. Because of the intermittent feed (feed stop when the needle enters the material) a positional change of the cuts in the clamp are avoided. This way, the Pfaff 3587 ensures the highest stitching accuracy and very high sewing performance. The Pfaff 3587 is the one and only in the world which performs 3,200 s.p.m. with intermittent feed.

The sophisticated sewing technology based on a seam-optimization system (needle-turning device + bobbin thread slide) ensures superb seam quality and a perfect stitch pattern in multi-directional sewing operations. The needle-turning device in combination with the bobbin thread slide and the vertical hook prevents slip stitches in highly decorative seam patterns with a circular seam contour.

The unique automatic clamp-changing system permits a completely overlapping fully automated operation. Only the material still has to be inserted manually.

„Ergonomics in the workplace“ is of great importance in the Pfaff 3587. The machine features a height adjustment which may be adjusted to the respective operator at the push of a button (optional). Sewing programs and corrections of the seams may be generated resp. executed right on the machine via a logically designed touch screen.

The Pfaff 3587 has all technical requirements to tackle even the most sophisticated and challenging sewing operations, e.g. in the sections shoe production, small leather good production or in the automotive interiors.