09/03/2020 – Textile-adapted energy generation — auf Deutsch lesen

TITV institute is concerned with harvesting electric energy

Textile-adapted energy converters collect electricity from where it costs nothing – from sunlight, movement, and waste heat.

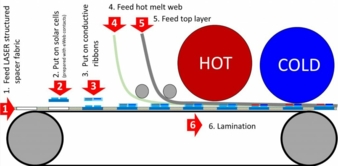

Recent R&D work of the TITV institute is concerned with harvesting electric energy using modularly designed units of textile-adapted polymer solar cells and piezoelectric foil converters. Assemblies for energy storage are also included. The purpose of this is to generate electricity from environmental energy for the autonomous power supply of smart textiles, energy self-sufficient sensors, the illumination of safety clothing and escape routes, the lighting of advertising materials (promotional flags, pavilons, parasols, billboards, etc.) as well as for the charge of battery packs. For this reason a simple and low-cost roll-to-roll production process has been developed for the manufacturing of textile-adapted energy harvesting and storage devices using off-the-shelf components.

Electrically conductive nonwoven

The manufacturing process consists of a pick-and-place step followed by a lamination step which are carried out on a continuously moving textile. The most important precondition for this process is the so called e-web. The e-web is an electrically conductive nonwoven made from a hot melt filled with silver particles which is manufactured using a technology developed at TITV facilities. e-web effects both electrical contact and adherence between the component pieces in a simultaneously ongoing process.

Energy harvesting modules can easily be tailored to any desired electrical performance parameters cutting them from a manufactured fabric roll laying in stock.

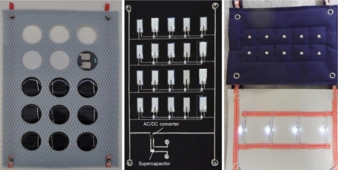

Two demonstrators were constructed: a flexible solar cell panel and a piezoelectric cascade generator.

The FlexSolar

The “FlexSolar” panel was built from a spacer fabric with a thickness of 3 mm and laser cut openings. After the placement of polymer solar cells electrical connections were formed with e-web in a lamination process. “FexSolar” is a flexible and air-permeable sandwich. Finishing with a polyethylene foil, which ensures high UV permeability, is an option for waterproofness.

The cascade

The piezoelectric cascade generator is used to produce electricity from alternating motion. The textile carrier is a fabric with embroidery made of an electrically conductive yarn creating a textile circuit board. The electric output voltage of a single cell upon bending lies near 8 V. A parallel connection of all converters results in a multiplication of the power output. In the lower part of the panel, a circuit for AC/DC conversion and a capacitor for energy storage were mounted on the fabric.

Using textile typical connection parts (e. g. snap fasteners or Velcro closures), the energy harvesting and storage modules can easily be put together to larger units including electrical appliances like textiles equipped with light-emitting diodes.

The K-Project Textile Competence Center Vorarlberg (no.860474) is funded within the context of COMET – Competence Centers for Excellent Technologies by the Austrian Ministry for Transport, Innovation and Technology, the Federal Ministry for Digital and Economic Affairs, and the federal states of Vienna, Tyrol and Vorarlberg. The programme is conducted by the Austrian Research Promotion Agency.

Dr. Wolfgang Scheibner, TITV Greiz